Activities

Mobility

We will lead the realization of a future-mobility society with displays, antennas, and sensors

Automotive glass

World leader in automotive glass for over 60 years

Automotive replacement glass

Your guarantee for certified automotive aftermarket glazing

Glass for transport vehicles

Our glazing solutions for transport and industrial vehicles

Worldwide operations

We are close to our customers worldwide

About us

Our vision

We will earn the trust of society by enabling a safe, comfortable and connected mobility.

Yoshio Takegawa

Our story

With over 100 years of history, we aim to continue contributing to society for years to come.

Our Philosophy

“Look Beyond” is AGC Group’s corporate philosophy on which all the activities of the Group are founded.

“Your Dreams, Our Challenge” is AGC Group’s brand statement created to fulfill our mission under the Group vision “Look Beyond”.

Business segments

Using the world’s top-class techniques cultivated through a history of technological innovation extending over 100 years, The AGC Group has continued to achieve the creation of new values in the business areas of Glass, Electronics, Chemicals, and Ceramics.

Glass

Architectural glass

Automotive glass

Automotive glass

Electronics

Glass substrates for displays

Electronic materials

Electronic materials

Chemicals

Chlor-alkali and urethane

Fluorochemicals & specialty chemicals

Life science

Fluorochemicals & specialty chemicals

Life science

Ceramics

Ceramics

New business

New business

R&D

Technology has always been our priority. The AGC Group has focused on the sophistication of its products and the advanced technology needed for their production. We have nurtured technologies, which are unparalleled in the world, in the fields of glass, electronics, chemistry, and ceramics.

AO (AO/AGC OPEN SQUARE) was established as a new creative base for AGC. AGC OPEN SQUARE is an open space where new value will be created.

Sustainability

The AGC Group has identified the major opportunities and risks (materiality) associated with simultaneously achieving the sustainable development of the planet and society and the sustainable growth of the Group.

We will continue striving to achieve the goal of net zero carbon by 2050 that we set last year, starting with our 2030 milestone of a 30% reduction in greenhouse gas emissions (compared to 2019). At the same time, we will accelerate the transformation of our business portfolio to be more carbon efficient.

AGC receives Honda Motor’s supplier award in the sustainability category

Response to climate change : Energy-saving automotive glass “Low-e Glass”

Investors

The AGC Automotive financial statement is part of the AGC Group report.

AGC Group overview

Founded in

1907

Employees

57,609

Group companies

201 Companies

FY2022 net sales

2,035.9 billion yen

Learn more about AGC Group

Our quality.

Everyone, every day

Everyone, every day

To achieve this commitment we work hard with our people, systems, processes and services. We strongly believe that we will succeed by working as a team and involving all our staff.

PEOPLE:

“People are our strength” and “Our Quality, Everyone every day” are fundamental slogans that AGC Automotive use as the core of our actions. We show our belief in our people through involvement. Monthly quality days in our factories and OEM quality day focus ongoing improvements.

SYSTEM:

AGC Automotive Europe has always been a strong believer in the benefits of a robust quality system. Since the beginning, our organization has always been committed to updating our quality systems according to international and client norms AGC Automotive Europe is fully compliant with IATF 16949 requirements.

PROCESS:

AGC Automotive Europe strives to continually improve its process efficiency and reliability. Our Right First Time mindset drives us to ever better performance

SERVICES:

We have invested significant resources in the service towards our clients, creating a skilled network of people able to support our customers with their daily requests and needs. Special attention has been made to match people with the same language, culture and approach in order to maximise our customer satisfaction.

AGC Automotive North America

AGC Automotive’s success is dependent on the performance of our suppliers. We are dedicated to developing a viable and robust Supply Chain to support AGC’s growth and sustainability. Through strategic business partnerships, it is our goal to achieve quality products and value for our company and our customers.

SUPPLIER MANUAL & PACKAGING GUIDELINE

The goal of the Supplier Manual and Packaging Guidelines is to standardize procedures for material, quality, purchasing, and packaging activities across all North American locations. These documents reflect AGC’s policies with its suppliers and ensure that AGC and its supply base are aligned with Global Automotive standards.

view Supplier Manual pdf

view Packaging Guidelines pdf

PURCHASE ORDER TERMS & CONDITIONS

view pdf

ISO/IATF QUALITY CERTIFICATIONS

IATF16949 Bellefontaine English IATF Certificate 2021

696740-000 Bellefontaine Portuguese IATF Certificate

IATF16949 Elizabethtown English IATF Certificate 2021

696740-001 Elizabethtown Portuguese IATF Certificate

IATF16949 Richmond English IATF Certificate 2021

IATF16949 Alabaster Certificate IATF 2021

696740-004 SLP Portuguese IATF Certificate

IATF16949 San Luis Potosí English IATF Certificate 2022

IATF16949 Guadalajara IATF Certificate 2022

ISO 9001 Bradford Certificate 2022

ISO ENVIRONMENTAL CERTIFICATION

view pdf

ENVIRONMENTAL POLICY

AGC Automotive Americas environmental policy

AGC Automotive Americas Responsible sourcing standards

AGC GROUP ENVIRONMENTAL POLICY

AGC Group environment policy

Responsible minerals sourcing policy

SAFETY SECURITY POLICY

view pdf

QUALITY POLICY

view pdf

AGC AUTOMOTIVE CANADA REPORTING DOCUMENTS

TRA Public Report Signed 2020

AODA multi year accessibility plan for the integrated accessibility standards regulation

TRANSPARENCY IN COVERAGE

In compliance with the Transparency in Coverage rule, we are providing the required link to help consumers know the cost of a covered item or service before receiving care, includes negotiated service rates and out-of-network allowed amounts between health plans and healthcare providers. This pricing information can be used by third parties, researchers, and app developers to help consumers better understand the costs associated with their health care.

Stage 1:

Here is the link to the Machine-Readable Files containing the costs for items and services: https://www.anthem.com/machine-readable-file/search

AGC FEIN # is 25-1059306

Here is the link to the Machine-Readable Files containing the costs for items and services: https://www.anthem.com/machine-readable-file/search

AGC FEIN # is 25-1059306

Stage 2:

Coming in 2023

Coming in 2023

Stage 3:

Coming in 2024

Coming in 2024

California regulations

California transparency in supply chains act declaration

California consumer privacy act notice addendum automotive

Products & solutions

Glass for displays

Cover Glass for Car-mounted Displays

Display Glazing

In-vehicle Glass Interface FeelInGlass®

Black Band Display

Glass for sensors and connected drive

Glass for LiDAR and camera Wideye®

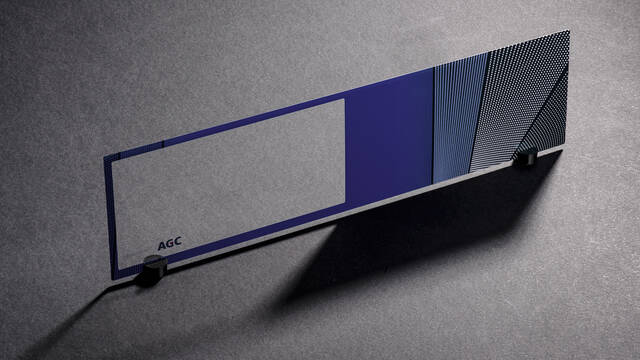

On-glass Antenna

5G-sub6 Glass Antennas

FIR Sensor-enabled Windshield

Mobility Connectivity Solutions Pulsaart®

Glass for windows

Smart Glazing Digital Curtain™

Low-e Glass

PV Cells Roof

HeatControl Windshield

Heated Wire Windshield

Head-up Display

Lightweight Glazing

Laminated Acoustic Glass

Infra-red Cut Glass Iris®

99% UV-cut Glass

Privacy Glass

Water Repellent Door Glass

Glass Applique

Pattern on Glass

Brightworks

Module Assembly Windows

Encapsulation

Laminated Glass Lamisafe™

Tempered Glass Temperlite™

Glass for trains

WaveThru™

Highly Insulating Glass

Highly Resistant Glass Chemically Tempered

Glass with Framing System

Emergency Side Windows

Innovation & technologies

R&D structure for innovation excellence

With R&D bases in Japan, Europe, and North America, AGC Automotive is the perfect partner both locally and globally for customers’ development needs. We lead the market in the innovation of materials, processing, coatings, simulation, composites, and production technologies which are then deployed to our production bases and used by customers all around the world.

Toward a sustainable future-mobility society

As CASE and MaaS become widespread, the efficient coordination of AGC Group capabilities involving glass, chemical, and materials technologies enable the combination of IT elements for sensors and displays with sleek, high-performance glazing.

Our state-of-the-art anechoic chambers based in Japan, Europe, and the United States enable us to work jointly with customers throughout the whole design, development, simulation, and production process.

New technology: our low-e coatings provide a panoramic roof that protects against heat

Our new Light Control Panoramic Roof with Low-e Coating uses a brand new, specially developed coating for vehicles.

The special Low-e film on the inner surface of the laminated glass allows high durability, unprecedented solar control, and heat insulation performance by combining inorganic materials and glass coating technologies. This greatly reduces the heat of summer and the cold of winter, previously drawbacks of glazed roofs.

Our high resin, polymer materials, and composite technologies are also used in the dimming function which instantly adjusts transmitted light levels, allowing the control of daylight entering the cabin environment, providing new enjoyment, comfort, and experiential values to driving.

AGC's Light Control Panoramic Roof with Low-E Coating Adopted in the LEXUS “RZ” Toyota LEXUS’ First Dedicated BEV Model

Mobility

Consumer driving needs and traveling habits are continuously evolving. A wave of changes - referred to as CASE (Connectivity, Autonomous, Shared, Electric) - is spreading through the automotive industry, while the new service format known as MaaS (Mobility as a Service) is becoming more widespread. As a result, Automobile is radically changing to Mobility with a new ecosystem of players.

To be an actor in this ongoing transition, AGC Automotive has identified Mobility as one of its Strategic Businesses, and especially focused on developing products and solutions of displays, antennas, and sensors as fields in which it can take advantage of AGC Group’s strengths.

Products & solutions for mobility

Displays

Antennas

Sensors

Displays

Cover glass for car-mounted displays

The displays installed in automobiles have become indispensable for connecting people and cars, such as navigation and the operation of in-vehicle devices. With the increase in information pesented such as driving-assistance systems, the displays are expected to be of even higher performance and larger size.

In 2013, we became the world's first company to establish a production system for car-mounted display cover glass that fully integrates every stage from raw glass to final processing, and launched the product for sale that year. In 2017, we also began manufacturing and offering curved cover glass in addition to the already available flat-surfaced cover glass.

As a leading company of cover glass for car-mounted displays, we will continue to promote technological innovation, and provide products with "new value and functions" in order to realize a safe, secure, and comfortable interior space.

Cover glass for car-mounted displays

Display glazing

In the future when Level 4 and 5 autonomous driving is realized, the window of mobility will become the role of a display, and there is a possibility that it will become a new medium of presenting information or HMI (Human Machine Interface). With that potential, we are working on marketing and developing display glazing that will enable the projection of high-contrast images onto transparent windows. In 2021, display glazing was adopted for digital signage service on the side windows of a taxi.

Display glazing

AGC's transparent glass screen “Glascene” adopted for digital signage service on side windows of a taxi

FeelInGlass®

New Mobility requires high level of connectivity with enhanced interior designs. FeelInGlass®, with its breakthrough vison, offers innovative glass solutions for incoming uses, such as decorative trims, display covers or smart surfaces. Thanks to its integrated supply-chain, an expertise in technology integration and CMF design, glass is tailor-made for functionality and state-of-the-art finishes.

www.feelinglass.eu

FeelInGlass® partners with IAC to develop innovative door panel - StreetSmartDoor

Antennas

5G-sub6 Glass Antennas

In anticipation of the era of connectivity requiring high-performance and highly reliable wireless communication technology for automobiles, capable of exchanging data securely anytime and anywhere, we have developed in-house "5G-sub6 On-Glass Antenna".

Without compromising the design of the vehicle, this technology makes it possible to integrate a 4x4 MIMO (Multi-Input Multi-Output) antenna system compatible with the 6 GHz band (with a bandwidth ranging from 617 MHz to 5000 MHz) in a single piece of front glass or by distributing it over the front and rear glass.

Incorporated into Halo.Car

Our 5G-sub6 Glass Antennas, known for its excellent connectivity stability, has also been adopted by US-based startup company Halo.Car for their remote-control system used in their car rental services.

Via 5G, it enables the transmission of video data captured by six cameras installed in the vehicle to the company's office. Operators can remotely control the vehicle while viewing the displayed video, enabling unmanned vehicle dispatch and pickup.

5G-sub6 Glass Antennas

Tri-polar R&D framework for on-glass antennas in EU, US, and Japan

In 2019, we established a development center, the first of its kind in the glass industry, equipped with anechoic chambers in the trilateral regions of Europe, US, and Japan. This facility is dedicated to accelerating the development of antenna infrastructure technologies for 5G and future high-speed communications. We aim to propose highly practical technologies that lead the way in realizing a mobility society.

Pulsaart®

Pulsaart, a start-up powered by AGC Automotive Europe, was created in Belgium in 2021. The modern technical equipment and extensive team expertise in the field make Pulsaart an end-to-end antenna system solution supplier for various mobility players: on road, rail, or air.

Whether it is the complete design of new antennas from scratch or the improvement of an existing product, Pulsaart engineers have state-of-the-art tools to turn clients' specifications into reality. The start-up has two unique anechoic chambers that offer fast, reliable measurements and efficient antenna physical optimization. As a result: reduced development time by simulation, rapid results by fast prototyping, and reduced testing time by replacing drive testing with virtual drive tests*.

*The technology is under development

Please contact to pulsaart@agc.com

Sensors

FIR Sensor-enabled Windshield

The automotive industry is expected to deploy ADAS on wide scale in the near future. Using AI and other high-tech solutions, ADAS helps mitigate human error and could ultimately eliminate most if not all traffic accidents. However, night vision accuracy requires further development.

AGC has developed FIR Sensor-enabled Windshield that maximizes the object recognition function of FIR (far-infrared rays) cameras, which are used as sensors to detect people in the dark.

How? The glass integrates a special material allowing the transmission of FIR within a portion of the windshield. This way, visible light sensing and FIR-sensor cameras can be installed high up in the windshield, which reduces the parallax between visible light sensing and FIR-sensor cameras. It is also advantageous for sensor fusion and for a wide field of view, early recognition of distant objects and protection of the sensors.

FIR Sensor-enabled Windshield

Wideye®, Glass for LiDAR and camera

Since 2016, Wideye has been totally focused on autonomous vehicle ecosystems with the vision of enabling ADAS deployment and bringing fully autonomous driving to reality.

In the mobility market where needs are continuously evolving towards ultimate safety, vehicles will be equipped with increasing numbers of sensors. The necessity to aesthetically integrate high-performance sensors in a reliable way is increasingly important. Wideye has made solving this challenge its specialty by providing the market with glass solutions for 360° sensor integration. Its innovative high-performance glass is transparent to near-infrared and has high optical quality, proving to be indispensable for the seamless installation of optical sensors such as LiDAR and cameras.

Discover our universe at www.wideye.vision or drop us an email at info@wideye.vision

Automotive glass

In 1956, AGC Automotive started automotive glass production in Japan. Our unique expertise covers the full supply chain from manufacturing the raw glass used for vehicle glazing, as well as repair glass for aftersales markets, and a large range of high value-added solutions aligned to new mobility needs. We are operating in 15 countries around the world, delivering our products to leading car manufacturers around the world.

Innovation for CASE era

In the automotive industry, the advancement of CASE is accelerating. In response to this trend, we have been the first in the world to develop a wide range of high-performance glass. Low-e Glass and Smart Glazing reduce the need to use air conditioning and extend the range of EVs due to their high heat-insulating performance. Laminated Acoustic Glass improves quietness and comfort inside EVs.

Low-e Glass

Smart Glazing Digital Curtain™

Laminated Acoustic Glass

R&D structure for innovation excellence

Manufacturing processes and product development for the realization of a sustainable society

In recent years, responses to climate change issues have received particular attention among social issues. In order to play a major role as a leader in automotive glass, we are striving to reduce CO2 emissions in the manufacturing process by developing and introducing world-class energy-saving glass manufacturing technology and actively utilizing DX.

In addition, we are also working to reduce CO2 emissions by developing and providing environmentally friendly products. Infra-red Cut Glass Iris® and UV Cut Glass with IR cut function enable fuel savings and reduce CO2 emissions by reducing air conditioning needs.

Infra-red Cut Glass Iris®

UV Cut Glass

Quality approach

Safety and quality are paramount. We strive for Zero Defects every day, and do not compromise on quality, meeting international safety standards. Our advanced quality is based on employee involvement and the continuous development of best practices. Our suppliers and partners must respect and follow our strict automotive quality standards, such as IATF 16949, ISO 9001, ISO 14001, ISO 45001, and so on.

Full-service mindset

We offer 360°services to our customers: unique co-design and CAD-design expertise, a collaborative approach to the full value chain, close contact with our customer teams, highly trained supply chain partners, customized deliveries (JIS), communication hotlines.

Automotive replacement glass

Quality standards

Every piece of glazing of AGC Automotive Replacement Glass conforms to the same high-quality standards as the original:

Homologation according to R43 regulations, 92/22 Directive, ANSI Z.26.1

Produced in ISO/TS 16949 certified plants

Meets all mechanical resistance requirements

Perfect fit to your car, reducing risk of breakage

Strict evaluation of optical properties

Submitted to tests as per ECE R43 safety regulations

Packed under optimal conditions to avoid damage during transportation

Superior service

AGC Automotive Replacement Glass provides a superior level of service with access to a wide product range with flexible ordering and delivery services.

Extensive product range covering most of the automotive park (for Europe the offer includes two brands: AGC Automotive and NordGlass)

High-technology products and related accessories (glue, trims, fitting tools, etc.)

Global flexible logistics including single units or dedicated trucks, daily deliveries and possibility to collect goods from the nearest warehouse

Stock management for large accounts

24/7 online ordering at www.agc-arg.com, including VIN search

Efficient customer service team

Distribution and fitting network

AGC Automotive Replacement Glass distributes automotive glazing and related products to spare part dealers, garages, wholesalers, and fitting chains on three continents: Europe, America, and Asia. We distribute the AGC Automotive and NordGlass brands in Europe, the AGC Automotive, NordGlass, Splintex and AP-Tech brands in the Americas and the AGC Automotive and AP-Tech brands in Japan.

Our warehouses supply the local market in Germany, the Netherlands, Denmark, Czech Republic, Poland, Russia, Ukraine, and Japan. In other European countries, distribution is managed by independent partners.

For glass repair and replacement in Europe, our fitting network operates under franchise agreements as Autoglass in Poland and Carglass in Czech Republic and Ukraine. We also have an extensive fitting operations network in Japan.

Glass for transport vehicles

AGC Automotive provides glazing solutions for transport and industrial vehicles: trains, buses, trucks, agricultural and construction vehicle cabins . We are committed to sustainable mobility, safety, comfort, and connectivity to enhance passengers' experiences. We design and manufacture "Tailor-made Systems" to equip your vehicles both on the outside and the inside.

Greener mobility

The AGC Automotive mindset, to build greener mobility for society, inspires our long-term partnership with public transportation industry stakeholders through our dedicated business line. As a world-leading glass company, we combine smart technology with the strictest requirements to provide best-in-class products like windscreens, side windows, rear and interior glazing.

Quality

From sourcing of raw materials, through the industrial processing and final inspection, our products are subjected to extremely rigorous quality controls. AGC Automotive manufactures glazing systems to the highest quality standards, giving you the support of a world leader in glazing. We have the broadest range of products certified to national or international standards:

IRIS & ISO/TS 22163

ISO 9001

ISO 14001

ISO 45001

EN 15152

ECE R43

ANSI Z26.1

UIC 651

BN 918511

GM/RT 2100

JIS R3213

BS 857

ISO 22752

EN 45545

NF F standards

L48

DIN 6701 (A1)

and others ..

Large product range

AGC Automotive product range provides glazing solutions granting optimal safety and comfort. From industrial cabs to high-speed trains, and from tempered glass to multi-laminated glass, we have products that suit your needs and constraints. Our technologies fit current and future market needs, integrating functions for a unique connected experience. Our technology range is unique and can be applied on all types of transport and industrial vehicles, for all types of glazing.

Flat glass or curved glass

Multi-layered laminated glass

Thermally tempered glass

Chemically tempered glass

Heated glass to defog or defrost

Antispall functions

Frame systems for quick replacement

Wavethru for best connectivity with coated glass

Coated and colored glass for thermal and visual comfort

Fire resistant interior glazing

Anti-reflective glass

Viral reduction glass

Patterned decorative interior glazing and so much more

Special solutions for trains

You can contact us for more information

Guaratingueta plant - Plants & Operations

Guaratinguetá, State of São Paulo • Brazil

AGC Headquarters - Headquarters

Tokyo • Japan

Regional Headquarters

Tokyo • Japan

Aichi plant - Plants & Operations

Aichi • Japan

Sagami plant - Plants & Operations

Kanagawa • Japan

AGC Fabritech - Plants & Operations

Tokyo • Japan

Quihuandao plant - Plants & Operations

Qinhuangdao, Hebei • China

Foshan plant - Plants & Operations

Foshan City, Guangdong Province • China

Bangpakong plant - Plants & Operations

Bangpakong • Thailand

Cikampek plant - Plants & Operations

Cikampek • Indonesia

Rewari plant - Plants & Operations

Rewari • India

Roorkee plant - Plants & Operations

Roorkee • India

Taloja plant - Plants & Operations

Taloja • India

Chennai plant - Plants & Operations

Chennai • India

Patan plant - Plants & Operations

Patan • India

Suzhou R&D Center - R&D Centers

Suzhou • China

Product Development Center - R&D Centers

Kanagawa • Japan

AGC Display Glass Yonezawa - Plants & Operations

Yamagata • Japan

AGC Yokohama Technical Center - R&D Centers

Kanagawa • Japan

Suzhou plant - Plants & Operations

Suzhou • China

Our vision

In recent years, technological innovation has progressed into new areas called "CASE" and "MaaS". The concept of cars and movement is about to change drastically. This trend requires more safe and comfortable transport, whilst dealing with urgent global environmental problems such as reducing CO2 emissions.

In order to respond, AGC Automotive identifies Mobility as a Strategic Business, and will create unique products and solutions that contribute to the realization of a safe, comfortable, and connected future-mobility society.

Yoshio Takegawa

In the journey to net zero carbon, we are working on both eco-friendly products that contribute to reducing CO2 emissions as well as upgrading our manufacturing processes towards carbon neutrality to contribute to the realization of a sustainable society.

Our strength is also being part of the AGC Group. Under the AGC Group Vision “Look Beyond”, we will pursue innovations to achieve Our Mission “AGC, an everyday essential part of our world”.

Under the brand statement "Your Dreams, Our Challenge", we will help make ever-greater achievements possible and bring bolder ideas to life.

Jean-Marc Meunier

Hiroyuki Ohtani

Michael Antonucci

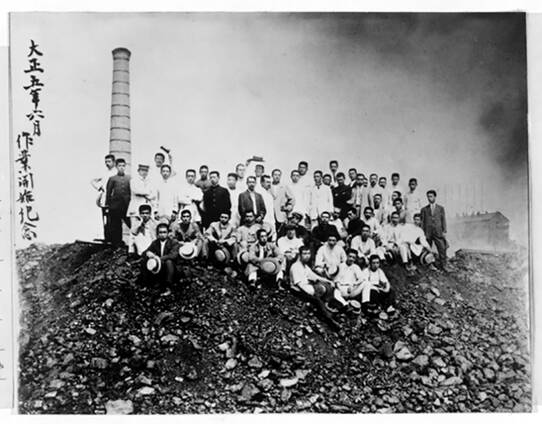

Our story

Establishment

In 1907, Toshiya Iwasaki decided to start domestic production of flat glass and established Asahi Glass Co., Ltd, (currently AGC Inc.). Under him, it succeeded in the first Japanese production of sheet glass. His pioneering spirit, summarized in the basic principle "Never take the easy way out, but confront difficulties" was the driving force behind AGC Group overcoming a succession of difficult business challenges and led to the company's subsequent dynamic growth.

Expanded into automotive glass business

In 1956, AGC began manufacturing automotive glass in response to growing demand for automobiles in Japan. Aichi and Sagami plants were established in 1970 and 1972 respectively.

Expansion in Southeast Asia. Technology enabled mass production

Due to new construction and expansion of manufacturing bases of Japanese automobile companies in Southeast Asia, Thai Safety Glass, currently AGC Automotive (Thailand) Co., Ltd., was established in 1974. Also, in 1976, PT Asahimas Flat Glass Tbk was established in Indonesia. Meanwhile, the industry’s first introduction of a gas furnace enabled the mass production of tempered glass for automobiles at one of AGC’s glass plants in Japan.

Business expansion in Europe, India, and North America

In 1981, AGC acquired Glaverbel, a long-established Belgian glass manufacturer excelling at manufacturing technology. In keeping with their traditional management spirit which always kept an eye on the global market, AGC actively expanded their business in Europe. This also contributed to the further growth of Glaverbel and invigorated the market.

In 1985, Asahi India Safety Glass Ltd., currently Asahi India Glass Ltd., was established in India.

Also in 1985, AGC established AP Techno Glass, currently AGC Automotive Americas Co., as a joint venture with the largest flat glass manufacturer in the United States, and it contributed to the region’s development through the production of automotive glass. AGC started operations at their Ohio plant in 1986 and at their Kentucky plant in 1989.

Business expansion in China and Europe

In 1995, a joint venture was established in China, followed by capital investment in QHSD, currently AGC Automotive (Qinhuangdao) Inc. To address production growth in all European regions, AGC acquired Sklo Union in the Czech Republic in 1990, started laminated glass production at Splintex in Belgium in 1992, invested capital in Bor Glassworks in Russia in 1997, and in 1998 expanded business in France and Italy through the acquisition of further European companies.

Transformation into a truly global company

AGC evolved into a truly global company in the 2000's. In 2002, AGC introduced the Global In-house Company System and Global Management System. In 2003, the automotive business was unified and branded as AGC Automotive. In 2007, the AGC Group brand was unified as AGC. In 2018, on its 100th anniversary, the corporate name Asahi Glass Company was changed to AGC Inc., to further enhance the integrated management framework for the AGC Group on a global scale.

Meanwhile, in line with the rapidly expanding Chinese automobile market, AGC made QHSD, currently AGC Automotive (Qinhuangdao) Inc., a subsidiary to strengthen the production capacity of Qinhuangdao plant in 2003. In 2005, AGC Automotive Hungary Ltd. started operations. In 2008, operations started at the Foshan plant (second plant) in China.

Business expansion in emerging markets and in the new mobility age

In the 2010's, positioning “business expansion in emerging markets” was one of its growth strategies. In 2014, AGC started operations at the Guaratingueta plant in Brazil, in 2016 at the San Luis Potosí plant in Mexico, and in 2019 at the Kenitra plant in Morocco. Meanwhile in China, operations started at the Suzhou plant (third plant), and integration of operations with the other two automotive glass production bases, Foshan Plant and Qinhuangdao Plant, was accelerated in 2015. Also, in order to enhance the automotive replacement glass business, AGC acquired NordGlass in Poland in 2015.

During the same period, vehicles became more and more connected, requiring ICT (Information and Communication Technology). In 2013, AGC’s subsidiary, AGC Display Glass Yonezawa started production of flat-surfaced cover glass for car-mounted displays on a dedicated production line in Japan. In 2017, AGC started mass production of 3D curved cover glass for car-mounted displays at Keihin Plant in Japan, which was a world first.

In addition, AGC enhanced on-glass antenna development including 5G and V2X, and opened two anechoic chambers in Belgium in 2019.

AGC begins mass production of 3D curved cover glass for car-mounted displays

AGC established a global tri-polar R&D framework for automotive on-glass antennas

Enhancing development of high value-added products for a mobility society

AGC Automotive identified Mobility as one of its Strategic Businesses, and especially focused on developing products and solutions of displays, antennas, and sensors as fields in which it can take advantage of AGC Group’s strengths. By leveraging the inherent strengths of the AGC Group, we enhanced the development of high value-added products for a sustainable, safe and comfortable mobility society.

Light control glass, "Digital Curtain® Dx", made its worldwide debut, adopted in Toyota’s new Harrier model.

AGC Automotive Europe launched the "Pulsaart" brand to reinforce antenna positioning.

Curved large cover glass for car-mounted dislays launched on the market, adopted by Cadillac. World’s first curved OLED display cover glass for a mass production vehicle.

Further acceleration towards a sustainable future-mobility society

AGC Automotive continues to develop unique and high value-added products and solutions that contribute to the realization of a safe and comfortable driving experience, affording a sustainable global environment while leading toward the realization of a true “mobility society”.

Augmented reality (AR) HUD presented on a demo car at CES in Las Vegas.

Started production of large 3D/complex-shaped cover glass for car-mounted displays at Suzhou plant in China.

Light control panoramic roof with low-e coating adopted in LEXUS RZ, LEXUS’s first 100% BEV model

News

April, 2024

•

Case Study & Article

Rail Professional Magazine in Conversation With: Yvain Cornet, COO at Pulsaart by AGC

March, 2024

•

Case Study & Article

Innovative glass materials for next-generation mobility

March, 2024

•

Case Study & Article

PVinMotion conference: AGC Automotive Europe unveils photovoltaic panoramic sunroof for passenger vehicles

January, 2024

•

Product Video

AGC technologies @ CES2024 - Digest

January, 2024

•

Press release

AGC Automotive 2023 retrospective

December, 2023

•

Press release

AGC's Thermal Comfort Panoramic Roof adoption on the market

December, 2023

•

Press release

AGC to showcase at CES 2024 cutting-edge glass solutions for mobility revolution

December, 2023

•

Product Video

AGC Automotive's Best Panoramic Roof

November, 2023

•

Press release

A solar facility operated by E.ON provides AGC Glass Hungary with a source of renewable energy.

November, 2023

•

Press release

We are excited to announce that AGC will be participating in CES 2024 for the second consecutive year!

September, 2023

•

Press release

AGC’s Digital Curtain™ Light Control Glass Adopted for Toyota’s “Century”

August, 2023

•

Press release

FeelInGlass at IAA Mobility München 2023

August, 2023

•

Press release

Wideye at IAA Mobility to showcase unique ADAS 360° sensor integration

July, 2023

•

Case Study & Article

AGC on-glass antennas help mobility industry adopt better connectivity

June, 2023

•

Case Study & Article

AGC has developed the world's first FIR sensor-enabled windshield, paving the way to enhanced driving safety

February, 2023

•

Press release

AGC and Saint Gobain partner for the decarbonization of flat glass manufacturing

January, 2023

•

Press release

AGC Automotive 2022 retrospective

December, 2022

•

Press release

Wideye® by AGC to showcase 360° FOV and unique ADAS sensor integrations at CES 2023

December, 2022

•

Press release

AGC to Exhibit Next-generation Mobility-enabling Products & Technologies at CES2023

December, 2022

•

Press release

FeelInGlass® by AGC, on its way to CES to unveil an exclusive immersive concept demonstrating glass integration abilities.

November, 2022

•

Product Video

Your panoramic glass roof gives a unique feeling of freedom

October, 2022

•

Case Study & Article

Testing & analysis of cleaning system with sensor glass cover. A collaborative project between Actasys and Wideye® by AGC.

September, 2022

•

Press release

Wideye® by AGC to display LiDAR sensor mounted in B-pillar at AutoSens show in Brussels

September, 2022

•

Case Study & Article

Integrating a LiDAR unit behind IR-transparent glass in a B-pillar. A collaborative project between Sony Depthsensing Solutions and Wideye by AGC.

July, 2022

•

Case Study & Article

Wideye by AGC, a corporate scale-up story made of business and human initiative

May, 2022

•

Press release

AGC's Light Control Panoramic Roof with Low-E Coating Adopted in the LEXUS “RZ” Toyota LEXUS’ First Dedicated BEV Model

April, 2022

•

Press release

AGC to Hold Special International Year of Glass 2022 Exhibition

March, 2022

•

Press release

AGC Receives Honda Motor's Supplier Award in the Sustainability Category

February, 2022

•

Press release

AGC Automotive retrospective 2021

January, 2022

•

Press release

AGC Sponsoring International Year of Glass 2022

January, 2022

•

Press release

Wideye by AGC at the Consumer Electronic Show 2022

January, 2022

•

Product Video

AGC Automotive and Eyelights : Be ready for the all-new Head-up-Display driving experience

January, 2022

•

Press release

AGC and EyeLights have joined forces to bring the Augmented Reality windshield to CES 2022

December, 2021

•

Product Video

AGC glass solutions, improving the safety and security of your drive

September, 2021

•

Press release

Opening Ceremony Held at AGC Yokohama Technical Center

May, 2021

•

Press release

Wideye announces reliable glass protective covers for sensors

March, 2021

•

Press release

AGC's transparent glass screen 'Glascene' adopted for digital signage service on side windows of taxis (Japan)

March, 2021

•

Press release

AGC Automotive 2020 retrospective

January, 2021

•

Press release

AGC Curved-Large Cover Glass for Car-mounted Displays to Be Used in New 2021 Cadillac Escalade

December, 2020

•

Product Video

AGC Automotive excellence and innovation in Head-up-display

November, 2020

•

Press release

AGC Automotive Europe celebrates World Quality Day throughout Europe

June, 2020

•

Press release

AGC's Light Control Glass, 'WONDERLITE™Dx', Makes its Worldwide Debut in Toyota's New Harrier

June, 2020

•

Product Video

How does AGC Automotive’s Heatcontrol thermal control technology work ?

June, 2020

•

Product Video

AGC heatcontrol-windshield combines thermal comfort in summer and silent de-icing in winter

May, 2020

•

Press release

AGC launches glass sanitary protection screens for shops and open spaces

April, 2020

•

Press release

AdaptVac Partners with AGC Biologics to Develop & Produce COVID-19 Vaccine

September, 2019

•

Press release

AGC Cover Glass for Car-mounted Displays to be Used in New Lexus RX Series

July, 2019

•

Press release

AGC honored at AutomotiveINNOVATIONS Awards 2019

June, 2019

•

Press release

Belron® and AGC sign a franchise agreement for vehicle glass repair and replacement networks in Poland and Czech Republic

May, 2019

•

Press release

DOCOMO, AGC and Ericsson Achieve World’s First 5G Communication Using Glass Antenna for 28 GHz

March, 2019

•

Press release

AGC Established a Global Tri-polar R&D Framework for Automotive On-glass Antennas

March, 2019

•

Press release

Inauguration of anechoic chambers of AGC Glass Europe in Gosselies

January, 2019

•

Press release

StreetSmart Door concept unveiled in Panasonic booth at Consumer Electronics Show 2019

September, 2018

•

Press release

AGC Automotive at Automechanika with Virtual Reality experience

September, 2018

•

Press release

AGC at Innotrans with smart glass for transportation

April, 2018

•

Press release

AGC Automotive Europe launches

October, 2017

•

Press release

AGC’s Kiriko Glasswork Adopted in New Lexus LS Model

September, 2017

•

Press release

AGC's Curved Cover Glass for Car-Mounted Displays Incorporated to the Mass Produced Vehicle for the First Time in the World

June, 2017

•

Press release

Railway Glass Made by AGC Asahi Glass Adopted for New Sleeper Train - “Twilight Express Mizukaze”

May, 2017

•

Press release

AGC Begins Mass Production of 3D Curved Cover Glass for Car-Mounted Displays

May, 2017

•

Press release

AGC Asahi Glass WONDERLITE™ Adopted for Luxury Train, "Train Suite Shiki-shima"

April, 2017

•

Press release

AGC Automotive Induver Morocco lays foundation stone for its automotive glass plant in Kenitra (Morocco)

November, 2016

•

Press release

New website for AGC Automotive, the largest automotive glassmaker in the world

September, 2016

•

Press release

AGC Automotive Europe launches ultra-dark grey glass on the market

August, 2016

•

Press release

AGC to Establish First Automotive Glass Production Base in North Africa

March, 2016

•

Press release

AGC to Expand Supply System of Cover Glass for Car-mounted Displays

March, 2016

•

Press release

AGC to Build a Second Float Glass Production Plant in Brazil

March, 2016

•

Press release

AGC Changes Name of Production Subsidiary in Suzhou, China

December, 2015

•

Press release

AGC Earns The Skin Cancer Foundation’s Seal of Recommendation for Automotive Windows in All Directions for the First Time in the World

November, 2015

•

Press release

World’s first All-around 99% UV Cut! AGC Launches UV Verre Premium Privashield

April, 2015

•

Press release

AGC Acquires NordGlass Poland, Active in Automotive Replacement Glass

March, 2015

•

Press release

AGC’s Glass Used for All Vehicles of New Hokuriku Shinkansen Line

March, 2015

•

Press release

AGC Becomes Official Sponsor of Japan Pavilion at EXPO Milano 2015

February, 2015

•

Press release

AGC to Have Exhibit at “Milan Design Week”, World’s Largest Design Festival, for First Time

December, 2014

•

Press release

AGC’s Global Branding Project for the World’s First Glass Bench Roof Wins the Grand Prize in the Corporate Communications Category of the PR Award Grand Prix

December, 2014

•

Product Video

AGC Light Control Glass WONDERLITE

September, 2014

•

Press release

AGC’s Light Control Glass WONDERLITE™ Selected for Panoramic Glass Roof on European Luxury Car

June, 2014

•

Press release

AGC holds Groundbreaking Ceremony at New Automotive Glass Plant in Mexico.

May, 2014

•

Press release

AGC Succeeds in Rolling SPOOL™, a 0.05 mm-thick Sheet Glass.

April, 2014

•

Press release

AGC’s Dragontrail™ Selected by 37 Electronic Device Brands

Contact

Products & solutions

Jobs & career

Replacement Glass

General inquiry

Products & solutions

Mobility and Automotive glass

Special glass for trains & industrial vehicles

AGC Automotive Europe S.A.

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

AGC Automotive Europe

+32-2-409-30-0

AGC Vidros do Brasil Ltda.

Brazil

Estrada Municipal Fazenda São Pedro

500 - Jardim Vista Alegre, City of Guaratinguetá

State of São Paulo, 12523-671, Brazil

500 - Jardim Vista Alegre, City of Guaratinguetá

State of São Paulo, 12523-671, Brazil

+55-12-3127-7100

https://agcbrasil.com/vidros-automotivos/

Automotive Company, AGC Inc.

Japan

1-5-1, Marunouchi, Chiyoda-ku

Tokyo 100-8405, Japan

Tokyo 100-8405, Japan

AGC Automotive Americas Co.

United States of America

34505 W. 12 Mile Road, Suite 300

Farmington Hills, MI 48331, USA

Farmington Hills, MI 48331, USA

AGC Automotive

+1-248-522-9300

AGC Automotive Europe S.A.

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

+32-2-409-30-0

Automotive Company, AGC Inc.

Japan

1-5-1, Marunouchi, Chiyoda-ku

Tokyo 100-8405, Japan

Tokyo 100-8405, Japan

AGC Automotive Europe S.A.

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

+32-2-409-30-0

AGC Automotive Europe S.A.

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

+32-2-409-30-0

Additional use of personal information

AGC will appropriately use personal information filled into your inquiries, in accordance with the AGC Personal Information Protection Policy.

AGC will appropriately use personal information within the AGC Group only for the purpose of responding to your inquiries. Any personal information in your inquiries is only used to reply to a given message, or to provide any related information.

In some cases, AGC will disclose, your personal information to its sub-contractors to the extent necessary to perform business operation. In such cases, AGC will execute an agreement(s) with those sub-contractors with respect to the handling the personal information, and make reasonable efforts to protect your personal information.

By contacting us, you agree to the terms "Additional Use of Personal information".

Replacement Glass

AGC Automotive Europe S.A.

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

AGC Automotive Replacement Glass

See sales offices contacts hereunder

http://www.agc-arg.eu

Automotive Company, AGC Inc.

Japan

1-5-1, Marunouchi, Chiyoda-ku

Tokyo 100-8405, Japan

Tokyo 100-8405, Japan

AGC Vidros do Brasil Ltda.

Brazil

Estrada Municipal Fazenda São Pedro

500 - Jardim Vista Alegre, City of Guaratinguetá

State of São Paulo, 12523-671, Brazil

500 - Jardim Vista Alegre, City of Guaratinguetá

State of São Paulo, 12523-671, Brazil

+55-12-3127-7100

https://agcbrasil.com/vidros-automotivos/

AGC Automotive Americas Co.

United States of America

4000 Gantz Road, Suite A

Grove City, Ohio 43123, USA

Grove City, Ohio 43123, USA

Sales offices

+49 32221863551

+420-225-296711

+31-344-636977

+45-43-613080

+7 (495) 1978728

+48-94-3465739

+38-044-2212099

+39-171-340312

Additional use of personal information

AGC will appropriately use personal information filled into your inquiries, in accordance with the AGC Personal Information Protection Policy.

AGC will appropriately use personal information within the AGC Group only for the purpose of responding to your inquiries. Any personal information in your inquiries is only used to reply to a given message, or to provide any related information.

In some cases, AGC will disclose, your personal information to its sub-contractors to the extent necessary to perform business operation. In such cases, AGC will execute an agreement(s) with those sub-contractors with respect to the handling the personal information, and make reasonable efforts to protect your personal information.

By contacting us, you agree to the terms "Additional Use of Personal information".

General inquiry

AGC Automotive Europe S.A.

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

AGC Automotive Europe

+32-2-409-30-0

AGC Vidros do Brasil Ltda.

Brazil

Estrada Municipal Fazenda São Pedro

500 - Jardim Vista Alegre, City of Guaratinguetá

State of São Paulo, 12523-671, Brazil

500 - Jardim Vista Alegre, City of Guaratinguetá

State of São Paulo, 12523-671, Brazil

+55-12-3127-7100

https://agcbrasil.com/vidros-automotivos/

Automotive Company, AGC Inc.

Japan

1-5-1, Marunouchi, Chiyoda-ku

Tokyo 100-8405, Japan

Tokyo 100-8405, Japan

AGC Automotive Americas Co.

United States of America

34505 W. 12 Mile Road, Suite 300

Farmington Hills, MI 48331, USA

Farmington Hills, MI 48331, USA

AGC Automotive

+1-248-522-9300

AGC Automotive Europe S.A.

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

+32-2-409-30-0

AGC Automotive Europe S.A.

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

+32-2-409-30-0

AGC Automotive Europe S.A.

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

+32-2-409-30-0

Additional use of personal information

AGC will appropriately use personal information filled into your inquiries, in accordance with the AGC Personal Information Protection Policy.

AGC will appropriately use personal information within the AGC Group only for the purpose of responding to your inquiries. Any personal information in your inquiries is only used to reply to a given message, or to provide any related information.

In some cases, AGC will disclose, your personal information to its sub-contractors to the extent necessary to perform business operation. In such cases, AGC will execute an agreement(s) with those sub-contractors with respect to the handling the personal information, and make reasonable efforts to protect your personal information.

By contacting us, you agree to the terms "Additional Use of Personal information".

Careers

Our Vision on Human Governance

At AGC Automotive Europe, our vision of human governance is based on taking human factors into account throughout any decision-making process. This human governance in turn leads to stronger management of the company.

It is based on full commitment to this course by all managers and is backed up by firm principles such as:

In operation, we view human development as a three-way partnership: between people and their aspirations, the business and its requirements, and human resources and their support forces.

Finally, it expresses our determination to build a company in which personal fulfilment leads to excellence.

Well-being

AGC Automotive Europe places the Well-Being of its staff at the center of their concerns and promotes a policy which unites the balance between company goals and Well-being at work.

People development

At AGC Automotive Europe, our people are our strength. Every person is unique and deserves the best development opportunities. We strive to give everyone an opportunity to grow as an employee and as a person.

Diversity, equity & inclusion

Today, the world is characterized by uncertainty and volatility, enhanced by shifting technology. We are not all equal in front of these challenges. It is our responsibility at AGC Automotive Europe to contribute to a successful SOCIAL TRANSITION. We want to secure a SAFE workplace for everyone, improve WELL-BEING in our jobs and DEVELOP our people. We aim for DIVERSITY, EQUITY and INCLUSION.

Environment

Career opportunities with AGC Europe

Have a look at our current job openings in our European Career Website!

If you wish more than automotive opportunities, select “display all” area & location.

Careers

Brand statements

“Your Dreams, Our Challenge”

The AGC Group’s business began more than 100 years ago with the ambitious aim of manufacturing the country’s first flat glass to help people’s daily life and industrial development.

Our unique materials, solutions and reliable partnerships have facilitated leading innovations across diverse industries and markets. Today, by working with others to combine knowledge and advanced technology, we help make ever greater achievements possible, and bring bolder ideas to life.

Our brand statement

Learn more about careers

Compensation & benefits

Competitive compensation

You'll be recognized with competitive compensation to provide financial wellness for you and your family.

Health

Medical, Dental, Vision and Prescription Drug benefits are available for you and your family. Professional coaching is available to assist you in making the right health care choices 24/7.

Employee Assistance Program provides prompt, confidential support with a range of personal and family issues that may affect all of us from time to time.

Well-being

We recognize that time away from work is essential for our associates to refresh and renew. Paid vacation and holidays are offered to our associates.

Dozens of discounts with great merchants and big brands will be offered to our associates to help the associate's well-being.

Financial security

Company -paid Life Insurnace and Accidental Death & Dismemberment with the option to enroll in Supplemental Life and Accidental Death & Dismemberment Insuranec helps provide financial support for you and your family during difficult times.

Our 401(K) plan helps you meet one of life's most important goals - financial security in retirement.

Environment

Find jobs

Supply Chain Management Coordinator

Elizabethtown, KY

Production Associate

Elizabethtown, KY

Maintenance Associate

Elizabethtown, KY

Process Engineer

Farmington Hills, MI

Product Engineer Leader

Farmington Hills, MI

Corporate Purchasing Manager

Farmington Hills, MI

Corporate Supply Chain Administrator

Farmington Hills, MI

Accountant

Elizabethtown, KY

Process Engineer

Elizabethtown, KY

Tooling Maintenance Associate

Elizabethtown, KY

AGC Group Career

Terms of use

About copyright, a trademark right, etc.

The contents on this site (a document, a photograph, an illustration, an animation, a sound, a program, etc.) are protected by the copyright which AGC Inc. (hereinafter "our company") and a third person have and cannot be diverted to some other purpose and reproduced without notice in our company.The contents on this site (a document, a photograph, an illustration, an animation, a sound, a program, etc.) are protected by the copyright which AGC Inc. (hereinafter "our company") and a third person have and cannot be diverted to some other purpose and reproduced without notice in our company.

Since the logo of the currently used at this site is the trademark of our company, it cannot be diverted to some other purpose and reproduced without notice in our company.

Qualification

Although our company has paid careful attention to become the information in which the information published to this site is newest and exact, as long as there is no special clear statement individually, it does not guarantee about validity, accuracy, etc. of contents of this site, and takes no responsibility.

Please understand beforehand that contents and URL of this site may be changed, interrupted or stopped without a preliminary announcement. Our company does not take responsibility regardless of a reason about any damage produced by discontinuation or stop of employment of change of the contents of this site, and this site.

It aims at the information service used as reference of investor judgment especially about investor information,It does not invite the stocks of our company to be purchased or sale. Please give me the terminal decision about investment so that it may be carried out in a user's own judgment.

About a link

As long as there is no agreement of our company separately, stretching a link to this site should cut down. Even if your company or you suffer damage from having stretched the link to this site without notice to our company, our company does not take any responsibility.

When the link is stretched from this site at sites other than this site (following "other sites"), it does not mean that our company recommends use, the contents of printing, etc. of the other sites, and does not mean that special relations between other sites, or the administrator and our company of those, such as tie-up relations, are in any way.

Sites those links stretched to this site managed in the responsibility of the establishment person of a site. Therefore, please follow the use conditions of other sites in use of other sites. Our company does not guarantee contents of the other sites, and does not take responsibility about all damage accompanying the use.

Privacy policy

Personal Information Protection Policy of the Company

Each company of the AGC Group (AGC Inc. and its subsidiaries, collectively, "AGC") recognizes the essential importance of the proper and adequate protection of the information of individuals, such as names, addresses, telephone numbers etc., which may be available to distinguish the identities of our customers, business partners, employees and all other parties concerned with our business operations (hereinafter collectively referred to as “Personal Information”).

Recognizing its responsibility to society, AGC hereby establishes the following basic policies (hereinafter “Policy”) to protect privacy of individuals and comply with laws and regulations enacted to protect Personal Information while conducting its business activities:

AGC will collect, use, and provide Personal Information through the fair and legal means.

Use within the Scope of Utilization Purpose

At the time of collecting any Personal Information, AGC will specify the purpose and scope of its use. AGC will use such collected Personal Information strictly within its originally intended scope of use and limited usage as necessary for business operations.

At the time of collecting any Personal Information, AGC will specify the purpose and scope of its use. AGC will use such collected Personal Information strictly within its originally intended scope of use and limited usage as necessary for business operations.

Authorization from the Individual

In case of necessity in which said Personal Information must be used beyond the above-mentioned scope, AGC will obtain an authorization from the individual to whom such Personal Information relates (hereinafter “Individual”) with regard to the planned use, except as allowed by relevant laws and regulations.

In case of necessity in which said Personal Information must be used beyond the above-mentioned scope, AGC will obtain an authorization from the individual to whom such Personal Information relates (hereinafter “Individual”) with regard to the planned use, except as allowed by relevant laws and regulations.

Security Measures to Protect Personal Information

When handling such Personal Information, AGC will strive to develop an organizational structure that has policies and procedures in place to strictly manage the Personal Information to prevent its illegal access, loss, falsification or leakage. To ensure the appropriate handling of personal information, AGC will continue to strengthen and improve internal systems, implement the necessary secure management measures in accordance with technological standards, and perform appropriate internal audits, etc.

When handling such Personal Information, AGC will strive to develop an organizational structure that has policies and procedures in place to strictly manage the Personal Information to prevent its illegal access, loss, falsification or leakage. To ensure the appropriate handling of personal information, AGC will continue to strengthen and improve internal systems, implement the necessary secure management measures in accordance with technological standards, and perform appropriate internal audits, etc.

Third Party Provision

Unless authorized by the Individual or allowed by relevant laws and regulations, AGC will not provide Personal Information to any third party. In addition, when providing such Personal Information to any third party as authorized or allowed above, AGC will conclude a contract with the third party or take any other measures that obligates the third party to be responsible for the management of the Personal Information to be provided, thereby preventing its leakage to any other party or other misuse.

Unless authorized by the Individual or allowed by relevant laws and regulations, AGC will not provide Personal Information to any third party. In addition, when providing such Personal Information to any third party as authorized or allowed above, AGC will conclude a contract with the third party or take any other measures that obligates the third party to be responsible for the management of the Personal Information to be provided, thereby preventing its leakage to any other party or other misuse.

AGC will promptly respond to requests from the Individual to disclose, correct, add and/or delete his or her Personal Information, to the extent required by relevant laws and regulations.

AGC will comply with relevant laws and regulations with regard to the protection of Personal Information, and also constantly review its implementation of the Policy, and strive to make further improvements.

AGC will completely inform of this Policy to all of its directors, offices and employees (including commissioned and dispatched personnel) as well as other concerned parties, to ensure that each of them understands the importance of the Policy and conduct him or herself in an appropriate manner to follow the Policy.

Purpose of Collecting Personal Information

AGC generally uses Personal Information for the purposes described below. (If a specific purpose of using Personal Information is clearly indicated, AGC will use the Personal Information for that specific purpose.) If AGC uses Personal Information for any other purposes, AGC will clearly indicate it before collecting it.

Responding to and dealing with general inquiries and requests and requests for materials;

Providing AGC's products and services and related information;

Conducting surveys to find out about the use of and need for AGC's products and services and improving AGC’s products and services;

Marketing, selling, and providing services for AGC's products;

Communicating for business purposes in the course of AGC's business activities.

Sharing of Personal Information

AGC jointly uses Personal Information with its group companies as shown in the table below.

| With whom Personal Information is jointly used | Each company of AGC Group Please see here for more information. |

| What Personal Information is jointly used | Name, address, telephone number, fax number, email address, place of work (department, job title, inquiry and transaction details etc.) |

| Purpose of jointly using Personal Information | The purposes described in the “Purpose of Collecting Personal Information” section above |

| Person responsible for managing Personal Information | AGC Inc. Please see here for AGC's address and representative. |

Provision of Personal Information to Third Parties

AGC will not disclose or provide your Personal Information to third parties unless:

You have given consent;

Personal Information is provided to subcontractors (and their subcontractors) that we engage to handle all or part of Personal Information to the extent necessary to achieve the purpose of using Personal Information;

Personal Information is provided to those listed in the “With whom Personal Information is jointly used” section above;

The disclosure or provision is required by law;

The disclosure or provision is required to protect the life, body, or property of a person, but it is difficult to obtain your consent;

It is necessary to cooperate with the central government or local governments when they perform their public administrative duties and obtaining your consent could adversely affect the execution of such duties.

Security Measures to Protect Personal Information

AGC has a Personal Information management structure and framework in place to prevent any unauthorized access to and loss, falsification, or leakage of Personal Information and strives to ensure appropriate security measures are taken. They are summarized below:

Personal Information Protection Policy

To ensure Personal Information is appropriately handled, AGC has this Personal Information Protection Policy, internal rules, and manuals in place to comply with various laws and regulations and deal with Personal Information requests and inquiries.

Rule for Handling Personal Information

AGC's Personal Information Protection Management Rule specifies how Personal Information should be handled at each stage of its handling process which includes collection, use, maintenance, provision, deletion, and disposal.

In addition, AGC regularly checks the following security measures to protect Personal Information:

Organizational security measures

AGC has appointed managers who are responsible for handling Personal Information. Staff who are authorized to handle Personal Information and the scope of Personal Information that they are authorized to handle are clearly defined. AGC has a well-established communication system in place to report any violation of the Personal Information Protection Act or AGC’s Personal Information Protection Management Rule.

Physical security measures

In the areas where Personal Information is handled, staff entry and exit is controlled and restrictions are placed on devices brought into such areas. Measures are put in place to prevent unauthorized staff from handling Personal Information.

Measures are put in place to prevent theft or loss of devices, electronic media, and paper documents which contain Personal Information.

Technical security measures

Access controls are put in place to limit the number of access privilege holders and the scope of the Personal Information database that they are authorized to access.

The information system which processes Personal Information is protected from unauthorized access by external parties and malicious software.

Administrative security measures

Training and/or e-learning sessions are provided to AGC staff to learn key points of handling Personal Information.

Monitoring of external environment factors

To handle Personal Information in other countries/regions, AGC regularly collects and monitors information on Personal Information protection systems of those countries/regions and implements security measures.

Data Protection Rights

You have data protection rights in accordance with the laws and regulations related to personal information of each country.

Procedures for Requesting Disclosure, Correction, and/or Deletion of Personal Information

Following is the outline of request procedures on Personal Information that AGC has collected. With regard to the specific procedures, please contact the service division to which you have provided your Personal Information.

Please contact from this page if you have not been informed which division should be approached for your inquiry.

Submitting requests

If you wish to request the disclosure, correction and/or deletion of your Personal Information, please contact the service division to which you have provided the Personal Information. AGC will send you the request form. Please fill in the form and return it to us by postal mail. In order to prevent potential leakage of the Personal Information, only requests made by the Owner of Personal Information will be accepted, except in case of the request being made by his or her legal representative.

If you wish to request the disclosure, correction and/or deletion of your Personal Information, please contact the service division to which you have provided the Personal Information. AGC will send you the request form. Please fill in the form and return it to us by postal mail. In order to prevent potential leakage of the Personal Information, only requests made by the Owner of Personal Information will be accepted, except in case of the request being made by his or her legal representative.

Documents to be included when submitting a request

In order to confirm that the individual submitting the request is in fact the Owner of Personal Information, please submit to us a copy of your driver's license or official residence certificate, along with the request form.

In order to confirm that the individual submitting the request is in fact the Owner of Personal Information, please submit to us a copy of your driver's license or official residence certificate, along with the request form.

AGC procedure for answering your request

After receiving your request, AGC will confirm the content of the request, and thereafter will send a response to it directly to you, the Owner, by postal mail. Please understand that in case AGC is unable to confirm the identity of the individual submitting the request, we may decline to answer the request. In addition, we ask for your understanding that while AGC will make efforts to respond to requests promptly, it is however possible that such response may take some time to ensure its accuracy.

After receiving your request, AGC will confirm the content of the request, and thereafter will send a response to it directly to you, the Owner, by postal mail. Please understand that in case AGC is unable to confirm the identity of the individual submitting the request, we may decline to answer the request. In addition, we ask for your understanding that while AGC will make efforts to respond to requests promptly, it is however possible that such response may take some time to ensure its accuracy.

To Make Inquiries about Your Personal Information

For other inquiries regarding your Personal Information, please contact the service division to which you have provided your Personal Information.

Please contact from this page if you have not been informed which division should be approached for your inquiry.

Access Logs

On the website, AGC records, in the form of an Access Log, basic information on computers that access the website. The information recorded in the Access Log does not contain any information which can identify a specific individual. AGC collects the information to conduct statistical analysis of your use of its website, provide you with information, and deliver an improved website experience to you.

To collect and analyze access logs, Google Analytics is installed on this website.

Google Analytics uses cookies to track behavioral data on visitors. These data do not contain any personal information that identifies users and will be handled based on Google’s privacy policy.

Further information about Google’s privacy policy may be obtained from http://www.google.com/privacy.html

Protection of Personal Information on Websites Linked to the AGC's Website

In some cases, the Company's website may include links to websites other than that of the Company or the Group. The Company takes no responsibility with regard to the protection of Personal Information or the contents on any website linked to the Company's website other than its own website or those of Group.

Web administrator

AGC Automotive Global Headquarters

1-5-1, Marunouchi, Chiyoda-ku, Tokyo 100-8405, JAPAN

For inquiry, please click here.

Site map

Products and solutions

Products and solutions

Innovation & technologies

Activities

Mobility

Automotive glass

Automotive replacement glass

Glass for transport vehicles

Worldwide operations

About us

Our vision

Our story

Our philosophy

Business segments

R&D

Sustainability

Investors

News

Contact

Careers

Europe

North America

AGC Group Career

Terms of use

Privacy policy

AGC Automotive Europe quality

AGC Automotive America policies

Web administrator

Search

Cover Glass for Car-mounted Displays

What is Cover Glass for Car-mounted Displays?

It is an in-vehicle cover glass, using AGC Dragontrail™, a specialty glass that is chemically strengthened. It ensures the high level of safety expected from an in-vehicle material.

Features and benefits

01

Superior aesthetics

Offers a high-quality interior given the quality perception of the glass itself, and contributes to improving the design of the vehicle interior when integrated into seamless dashboards.

02

High visibility and handling

Contributes to improving the visibility and handling of the display through optical coatings and decorative printing technology, which suppresses glare and finger marks by using AGC's unique technologies.

03

Our expertise is your guarantee

AGC has extensive experience with Cover Glass for Car-mounted Displays.

In 2013, we became the world's first company to establish a production system which integrated every stage from raw glass to final processing. In 2017, we developed a curved display glass in addition to the already available flat type.

Our cover glass has been adopted for more than 100 vehicle models, with total shipments of more than 25 million units.

Position on vehicle

Gallery

Technical information

01

High-strength glass technology

Cover glass uses AGC Dragontrail™, a specialty glass that is chemically strengthened.

AGC's unique design and validation process technology ensures the high level of safety expected from an in-vehicle material.

02

Forming technology

AGC realizes various shapes such as flat, curved, and complex curved shapes using our original technologies, and contributes to achieving a sleek and unified dashboard design.

03

Optical coating and printing technology

AGC plays a key role in improving both the viewing clarity and usability of displays through proprietary coating and decorative printing technologies covered by multiple patents.

You might be interested in

In-vehicle Glass Interface FeelInGlass®

Black Band Display

Contact us for more details

We are ready to share with you our vision and lead into the exciting world of innovation

Display Glazing

What is Display Glazing?

A laminated glass with a special screen film between two pieces of glass onto which an image can be projected.

Features and benefits

01

Excellent visibility and transparency

When the image is projected, a high contrast and clear image appears, but when there's no image, it's just transparent glass.

02

High safety and durability

It has the safety and durability required for automotive window glass.

03

Assumed use case (for outside)

We see a future where the mobility window can function as a source of information. For example, advertisements are projected on any vehicle window or messages are displayed for pedestrians or any new mobility needs.

04

Assumed use case (for inside)

We see a future where mobility can provide an exciting experience. For example, tourism mobility would operate while projecting images of recommended spots on the windows.

Position on vehicle

Gallery

Technical information

01

High visibility of images, low haze

Special film realizes sharp and clear images with high transparency.

02

Enable a large screen

You can see large-sized images on the window thanks to AGC's solution.

03

Bendable, fit for curved surface glazing

Special film made from a thin substrate.

04

Compatible with various projectors

You can use any type of consumer projector (e.g., short-focus projector) due to its wide viewing angle.

05

Standard maintenance

No special maintenance is needed, as it is a special film laminated between two glasses (completely glass surface).

06

Safety, sustainable

Passed safety evaluation for automotive and realized high durability guaranteed by AGC.

You might be interested in

Black Band Display

Smart Glazing Digital Curtain™

Contact us for more details

We are ready to share with you our vision and lead into the exciting world of innovation

In-vehicle Glass Interface FeelInGlass®

Position on vehicle

Gallery

You might be interested in

Mobility Connectivity Solutions Pulsaart®

Infra-red Cut Glass Iris®

Contact us for more details

We are ready to share with you our vision and lead into the exciting world of innovation

Black Band Display

What is Black Band Display?