事業内容

モビリティ

ディスプレイ・アンテナ・センサーで、

モビリティ社会の実現をリードします。

モビリティ社会の実現をリードします。

自動車用ガラス

60年以上の実績を持つ、

新車向け自動車用ガラスビジネスのリーディングカンパニーです。

新車向け自動車用ガラスビジネスのリーディングカンパニーです。

自動車用補修ガラス

高品質な自動車用補修ガラスとサービスを提供します。

輸送機器・産業車両用ガラス

輸送機器・産業車両用ガラス向け

ソリューションを提供します

ソリューションを提供します

グローバルな生産体制

世界各地で高品質な製品と ソリューションを提供します。

企業情報

ビジョン

サステナブルな

モビリティ社会の実現を

リードすることを目指します。

モビリティ社会の実現を

リードすることを目指します。

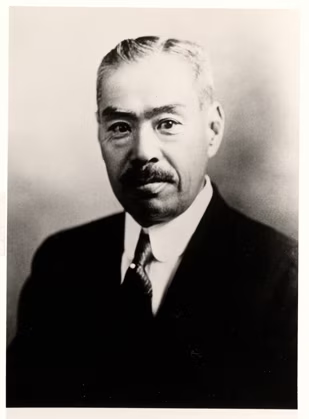

竹川 善雄

ヒストリー

100余年の歴史を越えて

新しい時代の社会づくりに

貢献していきます

新しい時代の社会づくりに

貢献していきます

企業理念

"Look Beyond" は、AGCグループのすべての事業活動、社会活動を貫く企業理念です。

AGCグループは、グループビジョン“Look Beyond”に示す私たちのパーパス“AGC、いつも世界の大事な一部”の実現に向け、ブランドステートメント“Your Dreams, Our Challenge”を制定しました。

事業概要

AGCは100年以上にわたる技術革新の歴史の中で培った世界トップレベルの技術を強みに、「ガラス」「電子」「化学品」「セラミックス」の事業領域で新たな価値創造に挑戦しています。

ガラス

建築用ガラス

自動車用ガラス

自動車用ガラス

電子

ディスプレイ用ガラス

電子部材

電子部材

化学

エッセンシャルケミカルズ

パフォーマンスケミカルズ

パフォーマンスケミカルズ

セラミックス

セラミックス

ライフサイエンス

ライフサイエンス

研究開発

AGCはガラス、エレクトロニクス、化学品、セラミックス、多様な技術を組み合わせることにより、新たな価値を創造します。

AO(アオ/AGC OPEN SQUARE)は、新たな価値を創り出していくAGCの新たな創造拠点として誕生しました。

サステナビリティ

AGCグループでは長期的な社会課題の動向を踏まえ、地球・社会の持続的発展とAGCグループの持続的成長の両立を実現する上で重要となる機会とリスクを特定しています。

AGCグループでは、2050年に「カーボン・ネットゼロ」を目指すことを宣言しています。そのマイルストーンとして、2030年までにGHG排出量30%削減およびGHG排出量売上高原単位50%削減(いずれも2019年比)を掲げています。GHG排出量低減に向けた取り組みに一層注力するとともに、環境対応型の製品を多数開発しており、今後さらに拡大していきます。

AGC、本田技研工業より優良感謝賞 「サステナビリティ部門」 を受賞

気候変動への対応~エコガラス「Low-e Glass」

株主・投資家情報

最新決算発表資料やIRニュースは、こちらをご覧ください。

AGCグループ 企業情報

創立

1907

従業員数

56,724

グループ企業

194社

2023年売上高

2兆193億円

AGCグループをもっと知る

Our quality.

Everyone, every day

Everyone, every day

To achieve this commitment we work hard with our people, systems, processes and services. We strongly believe that we will succeed by working as a team and involving all our staff.

PEOPLE:

“People are our strength” and “Our Quality, Everyone every day” are fundamental slogans that AGC Automotive use as the core of our actions. We show our belief in our people through involvement. Monthly quality days in our factories and OEM quality day focus ongoing improvements.

SYSTEM:

AGC Automotive Europe has always been a strong believer in the benefits of a robust quality system. Since the beginning, our organization has always been committed to updating our quality systems according to international and client norms AGC Automotive Europe is fully compliant with IATF 16949 requirements.

PROCESS:

AGC Automotive Europe strives to continually improve its process efficiency and reliability. Our Right First Time mindset drives us to ever better performance

SERVICES:

We have invested significant resources in the service towards our clients, creating a skilled network of people able to support our customers with their daily requests and needs. Special attention has been made to match people with the same language, culture and approach in order to maximise our customer satisfaction.

AGC Automotive North America

AGC Automotive’s success is dependent on the performance of our suppliers. We are dedicated to developing a viable and robust Supply Chain to support AGC’s growth and sustainability. Through strategic business partnerships, it is our goal to achieve quality products and value for our company and our customers.

SUPPLIER MANUAL & PACKAGING GUIDELINE

The goal of the Supplier Manual and Packaging Guidelines is to standardize procedures for material, quality, purchasing, and packaging activities across all North American locations. These documents reflect AGC’s policies with its suppliers and ensure that AGC and its supply base are aligned with Global Automotive standards.

Americas Supplier Manual

AANA Packaging Guidelines

PURCHASE ORDER TERMS & CONDITIONS

AANA Purchase Order Terms and Conditions

ENVIRONMENTAL POLICY

AGC Automotive Americas Responsible Sourcing Standards

AGC GROUP ENVIRONMENTAL POLICY

Responsible Minerals Sourcing Policy

TRANSPARENCY IN COVERAGE

In compliance with the Transparency in Coverage rule, we are providing the required link to help consumers know the cost of a covered item or service before receiving care, includes negotiated service rates and out-of-network allowed amounts between health plans and healthcare providers. This pricing information can be used by third parties, researchers, and app developers to help consumers better understand the costs associated with their health care.

Stage 1:

Here is the link to the Machine-Readable Files containing the costs for items and services: https://www.anthem.com/machine-readable-file/search

AGC FEIN # is 25-1059306

Here is the link to the Machine-Readable Files containing the costs for items and services: https://www.anthem.com/machine-readable-file/search

AGC FEIN # is 25-1059306

Stage 2:

Coming in 2023

Coming in 2023

Stage 3:

Coming in 2024

Coming in 2024

CALIFORNIA REGULATIONS

California Transparency in Supply Chains Act Declaration

California Consumer Privacy Act Notice Addendum Automotive

SUPPLIER INFORMATION SECURITY

AGC Automotive Americas Supplier Information Security Policy

製品・ソリューション

ディスプレイ用ガラス

車載ディスプレイ用カバーガラス

車窓ディスプレイ

黒セラ部投影HUD

(Black Band Display)

(Black Band Display)

センサー・アンテナ用ガラス

LiDAR用カバーガラス Wideye®

ガラスアンテナ

5G通信対応ガラスアンテナ

FIRカメラ対応フロントガラス

車窓用ガラス

調光ガラス Digital Curtain®

Low-eガラス

透明導電膜付きウィンドシールド

導電ワイヤー封入ウィンドシールド

ヘッドアップディスプレイ

薄板合わせガラス

遮音ガラス サウンドベール™

赤外線カットガラス クールベール®

99%UVカットガラス

プライバシーガラス マイベール™

ドア撥水ガラス ウェルビュー™

ピラー用カバーガラス

モジュールアッシーウィンドウ

合わせガラス LAMISAFE™

強化ガラス TEMPERLITE™

高断熱ガラス

化学強化ガラス

曇りにくいガラス エグゼビュー®

技術開発

イノベーションを生み出す

技術開発体制

技術開発体制

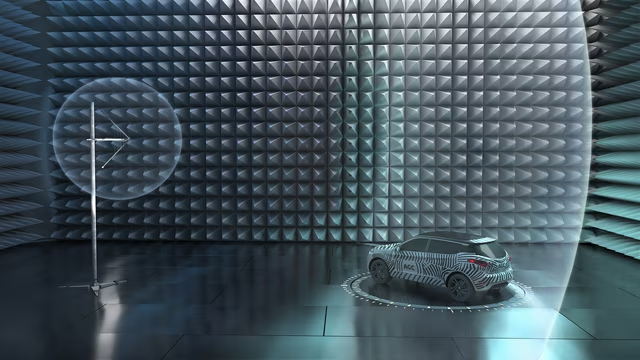

AGCオートモーティブは日本、中国、ヨーロッパ、北米に研究開発拠点を持ち、現地のニーズに基づいた開発活動ならびに4極で相互に連携したグローバル開発活動を行っています。

開発分野は素材開発・ガラス加工技術開発・コーティング技術開発、シミュレーション技術開発・複合化技術開発ならびに自動車ガラス生産技術開発を中心に、自動車用ガラスの新製品開発・新技術開発を行い、世界各地のお客様ならびに当社の生産拠点へ展開しています。

また、AGCグループの開発組織とも連携したより広範囲な開発活動も行っています。特にAGCグループの持つガラス・セラミクス・化学・エレクトロニクス関連技術ならびに共通基盤技術を融合させた自動車向けの技術開発と総合力で、素材から用途まで幅広くお客様へ提案活動を行っています。

サステナブルな

モビリティ社会の実現に向けて

モビリティ社会の実現に向けて

自動車業界にはCASEやMaaSという変革の波が押し寄せており、その変革に対応すべく、当社では自動車用ガラスアンテナやセンサー対応カバーガラス、車窓ディスプレイといった製品を開発しています。それらの開発にはガラス材料技術、化学材料技術といったAGCグループの総合力も活かされており、高機能な製品をいち早く開発できる独自の強みとなっています。

また、当社では日本、ヨーロッパ、北米の開発拠点に最先端の電波暗室を備えており、自動車用ガラスアンテナ開発体制を整えています。 50年以上にわたるガラスアンテナ開発の知見で設計から開発、シミュレーション、製造までお客様を支援し、V2X時代の高速通信を支えます。

新開発:

Low-eコート付き調光パノラマルーフが

快適性向上に加え、CO2排出削減にも貢献

Low-eコート付き調光パノラマルーフが

快適性向上に加え、CO2排出削減にも貢献

当社の新製品であるLow-eコート付き調光パノラマルーフには新規に開発した車載用特殊Low-eコーティングが採用されています。

合わせガラスの車内面にコーティングされた特殊Low-e膜は、これまで培ってきた無機材料技術やガラスコーティング技術の融合により高い耐久性と今までにない遮熱・断熱性能を実現し、これまでパノラマサンルーフの課題だった夏の暑さ・冬の寒さを大きく改善します。

瞬時に透過光を制御し車内の光環境を調整可能とする調光機能には当社の高い樹脂・高分子材料技術や複合化技術が活かされ、クルマに新しい楽しさ、快適さ、体験価値を提供します。

また、エアコン負荷を低減して燃費向上によりCO2排出を削減、EVでは航続距離延長にも貢献します。シェードレス設定も可能となり車両軽量化にも寄与します。

AGCのLow-eコート付き調光パノラマルーフが トヨタ自動車株式会社 LEXUS初のBEV専用モデル「RZ」に採用

モビリティ

生活者の移動ニーズは日々変化し、自動車業界ではCASEという変革の波とMaaSと呼ばれる新たなサービス形態の普及が進む中で、自動車は多様なプレイヤーによるエコシステムを持ったモビリティへと変化しています。AGCオートモーティブは「モビリティ」領域を戦略事業の一つと位置付け、特にAGCグループの強みを発揮できる3分野:ディスプレイ・アンテナ・センサーの製品やソリューションの開発に注力しています。

また、地域や国によって異なるモビリティニーズに対応するため、市場調査や製品企画、技術開発、ベンチマーク活動、そしてサードパーティーとの共同市場テストを各地域で進めています。この取り組みを通じて、常に時代の一歩先を行くソリューションをお客様に提供することを目指しています。

AGCの5G通信対応ガラスアンテナ 米国Halo.Car社との実証実験を経て商用化へ

モビリティ向け

製品・ソリューション

製品・ソリューション

ディスプレイ

アンテナ

センサー

ディスプレイ

車載ディスプレイ用

カバーガラス

カバーガラス

自動車に搭載されているディスプレイはナビゲーションや車内機器の操作等、ヒトとクルマをつなぐ必要不可欠な存在となっており、今後も運転支援等の情報表示の増加に伴い、更なる高機能化、大型化が見込まれています。

当社は2013年に世界で初めて車載ディスプレイ用カバーガラスの素板から加工まで一貫生産する体制を整えてお客様への提供を開始し、2017年からは平面形状に加えて曲面形状のカバーガラスも生産しています。車載ディスプレイ用カバーガラスのリーディングカンパニーとして、今後も「安心・安全・快適」な車内空間実現のために、「新たな価値・機能」をプラスした製品を提供できるよう技術革新を進めていきます。

車載ディスプレイ用カバーガラス

車窓ディスプレイ

高度自動運転(Lv.4-5)が実現した将来には、モビリティの窓がディスプレイの役割を果たし、情報発信やHMI(Human Machine Interface)として機能する可能性があります。

当社は、その可能性を見据え、透明な窓ガラスに高コントラストな映像を投影できる車窓ディスプレイのマーケティングおよび開発に取り組んでいます。2021年には、タクシーの車窓に広告を表示するモビリティサイネージサービスに採用されています。

車窓ディスプレイ

AGCのガラス製透明スクリーン Glascene®が車窓モビリティサイネージサービスに採用

アンテナ

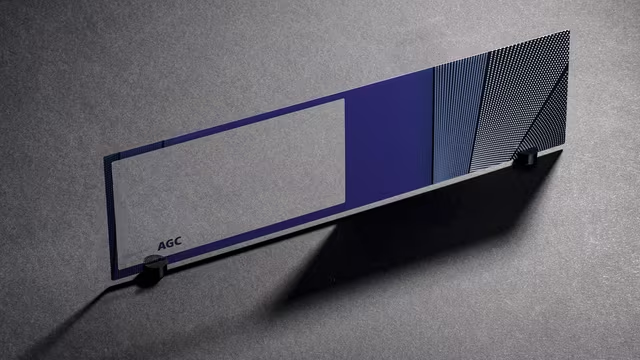

5G通信対応ガラスアンテナ

いつどこでも、確実にデータをやり取りできる高性能・高信頼の自動車用無線通信技術が求められるコネクテッド化の時代を見据え、当社では「5G通信対応ガラスアンテナ」を開発しました。

車体のデザインを損なうことなく、6GHz帯(帯域幅は617MHz-5000MHz)対応の4×4MIMO(Multi-Input Multi-Output)アンテナシステムを1枚のフロントガラスの中、もしくはフロントとリアのガラスに分散配置することができます。

Halo.Carのリモート操作システムに

導入

導入

当社の5G通信対応ガラスアンテナは、その優れた接続安定性から、レンタカーサービスを提供する米国のスタートアップ企業Halo.Carの「リモート操縦システム」にも採用されています。

自動車に設置した6台のカメラで撮影した映像データを、5Gを利用して同社オフィスのサイトに伝送。映し出された映像をオペレータが見ながらリモート操縦し、無人での配車・引き取りを可能にしています。

高性能と意匠性を兼ね備える AGCの5G通信対応ガラスアンテナ

日米欧3極でアンテナ技術開発を推進

当社は2019年に、ガラス業界で初めて日欧米3極に電波暗室を備えた開発拠点を整備しています。5Gやその先の高速通信のためのアンテナ基盤技術開発を加速し、モビリティ社会の実現をリードする実用性の高い技術を提案していきます。

センサー

FIRカメラ対応フロントガラス

交通事故ゼロに向け、近年ではAIなどを活用して人為的ミスをカバーするADASの普及に大きな期待が寄せられています。一方で、夜間のADASの効力はまだ十分とはいえない状況です。

そこで当社では、暗闇でも人を発見できるセンサーとして使われるFIR(遠赤外線)カメラの物体認識機能を最大限に発揮する「FIRカメラ対応フロントガラス」を開発しました。

「FIRカメラ対応フロントガラス」は、フロントガラスの一部にFIRを透過する特殊材料を一体化しています。フロントガラス内の高い位置に可視カメラとFIRカメラを設置できるため、可視カメラとFIRカメラの視差が少なくなり、センサーフュージョンに有利になります。また、広い視野の確保や遠方物体の早期認識、センサーの保護にも有利になります。

FIRカメラ搭載フロントガラスで、夜間の歩行者交通事故ゼロに挑戦するAGC)

LiDAR用カバーガラス Wideye®

自動運転を支える重要な技術として、当社はセンシングに用いられる波長領域に最適な透明性を持ったLiDAR用カバーガラス「Wideye」を開発しました。

高い専門知識を有したWideyeチームが、特殊な赤外線透過ガラスを用いてLiDARと車体を統合する為のソリューションを提供します。

LiDAR用カバーガラス Wideye®

自動車用ガラス

AGCオートモーティブのコア事業である「自動車用窓ガラス」は、1956年に日本で生産を開始しました。

自動車用ガラス素板(もといた)の製造から補修用ガラスの製造までのサプライチェーンを構築しており、多岐にわたる高付加価値製品を世界15ヵ国で生産しています。

当社の製品は世界中の自動車メーカーに採用されており、自動車用ガラスで世界トップレベルのシェアを有しています。

CASE時代に向けた

製品開発への取り組み

製品開発への取り組み

自動車業界にはCASEという変革の波が押し寄せ、その変化はさらに加速しています。

当社ではこの変化に対応すべく、例えば高い遮熱・断熱性能でエアコン負荷を低減し、EVの航続距離延長に寄与する「Low-Eガラス」や「調光ガラス Digital Curtain®」、EV車内の静粛性を向上させる「遮音ガラス サウンドベール®」など、世界に先駆けて開発・提供しています。

Low-eガラス

調光ガラス Digital Curtain®

遮音ガラス サウンドベール®

イノベーションを生み出す技術開発体制

サステナブルな社会の実現のための

製造工程や製品開発への取り組み

製造工程や製品開発への取り組み

近年、気候変動問題への対応が社会課題の中でも特に重要視されています。

当社は業界リーダーとして主要な役割を果たすべく、世界トップレベルの省エネガラス製造技術の開発・導入やDXの積極的な活用を進めるなど、製造工程におけるCO2排出量低減に努めています。

また、高い遮熱性能でエアコン負荷を低減し、燃費削減に寄与する「赤外線カットガラス クールベール」や「IRカット機能付き UVカットガラス」などの環境に配慮した製品を開発・提供することでもCO2排出量低減に取り組んでいます。

赤外線カットガラス クールベール®

UVカットガラス

品質向上への取り組み

安全と品質はお客様にとって最優先事項です。当社は「ゼロ・ディフェクト」の実現に向け妥協せず努力を続けながら、国際的な安全基準を満たした高品質な製品を提供しています。

この優れた品質は、全従業員によるベストプラクティスの継続的な開発に基づいて実現されています。また、厳選されたサプライヤー様やパートナー企業様には、当社の厳格な品質基準を遵守していただいています。

サービス向上への取り組み

多様化する消費者ニーズに合わせて自動車をカスタマイズするためのオプションも増え、その結果、自動車設計や製造プロセスは複雑化してきています。当社は、そのような状況でのお客様の課題を解決するべく高品質なサービスを提供しています。

サプライチェーン部門では、オンラインサポートやジャストインタイム・デリバリー、ジャストイン・シーケンス等により、経験豊富なスタッフがお客様のご要望に迅速にお応えしています。

自動車用補修ガラス

品質向上への取り組み

AGCオートモーティブの自動車用補修ガラスは、AGCの「品質マネジメントシステム」に基づいて新車向け自動車ガラスと同等の厳格な品質管理を行っています。

ガラスは国際的な共通規格であるISO/TS16949に準拠した工場で生産され、衝突時の安全性、光の透過性、耐候性、耐摩耗性、透視ひずみ等の様々な試験や検査を行っており、国内や国際的な安全基準を満たした高品質な製品を提供しています。

サービス向上への

取り組み

取り組み

様々なお客様のご要望にお応えするため、高品質なサービスをグローバルに提供しています。

各自動車メーカーの車種・型式毎に取り揃えている純正ガラスのほか、当社が独自に開発した高機能ガラスや、ガラス施工に必要な接着剤・付属部品・工具などの関連資材も取り揃えています。

また、お客様がタイムリーかつスムースにオーダーしていただけるよう、オンラインでの自動車ガラス発注システムやカスタマーサポート体制も整えています。

物流品質向上や

ガラス交換サービス事業への

取り組み

ガラス交換サービス事業への

取り組み

日本では「AGC Automotive」と「AP Technoglass」のブランド名で自動車ディーラーや自動車ガラス販売店、施工店等へ製品を提供しています。AGCグループ会社のオートグラス株式会社が全国の主要都市に営業在庫拠点を展開し、お客様への即納体制、素早い配送サービスを実現しています。

アメリカでは「AGC Automotive」、「NordGlass」、「Splintex」、「AP Technoglass」のブランド名や、欧州では「AGC Automotive」と「NordGlass」のブランド名でドイツ、ベネルクス、デンマーク、チェコ、ポーランド、ウクライナの営業在庫拠点やパートナー企業とのネットワークを通じて、迅速かつ柔軟な配送サービスを実現しています。

また、ガラス交換・補修サービスについては、日本ではAGCグループの施工会社を通じて、欧州ではフランチャイズ契約の下、ポーランドで「Autoglass」、チェコとウクライナで「Carglass」のブランド名で事業を展開しています。

輸送機器・産業車両用ガラス

AGCオートモーティブは鉄道やバス、農業機械や建設機械など様々な車両向けのガラス製品やソリューションの提供を通じて、「安全」「快適」で「つながる」サステナブルなモビリティ社会の実現をリードすることを目指します。

サステナブルな社会の実現のための

製造工程や製品開発への取り組み

製造工程や製品開発への取り組み

ガラス業界のリーディングカンパニーとして環境に優しいモビリティ社会を実現するため、独自の環境マネジメント体制や環境目標のもと、先進の技術を用いながら製品ライフサイクル全体での環境負荷低減を目指した製品を開発しています。

夏の暑さ・冬の寒さを防ぐエコガラス「Low-Eペアガラス」が「TWILIGHT EXPRESS 瑞風(みずかぜ)」に採用

品質向上への取り組み

原材料調達から生産加工、最終検査に至るまで、AGCの「品質マネジメントシステム」に基づいて厳格な品質管理を行い、国内や国際的な安全基準を満たした高品質な製品を提供しています。

IRIS & ISO/TS 22163

ISO 9001

ISO 14001

ISO 45001

EN 15152

ECE R43

ANSI Z26.1

UIC 651

BN 918511

GM/RT 2100

JIS R3213

BS 857

ISO 22752

EN 45545

NF F standards

L48

DIN 6701 (A1)

and others ..

お客様のニーズに合わせた

幅広い製品・ソリューションを提供

幅広い製品・ソリューションを提供

新幹線や寝台列車、バス、建設機械、トラクターなど様々な車両向けに、ウィンドシールドやサイドウインドウ、内装用など様々な部位において安全性や快適性、デザイン性の向上を実現する高機能ガラスやソリューションを提供しています。

光の透過を自在にコントロールする「調光ガラス」

断熱効果で結露を抑える「複層ガラス」

防曇・融氷する「電熱ガラス」

紫外線から肌を守る「UVカットガラス」

暑さを低減する「赤外線カットガラス」

車体軽量化に寄与する「化学強化ガラス」

車内デザイン性を向上する「内装用ガラス」

強化ガラス

合わせガラス

AGCの調光ガラス「WONDERLITE®」がクルーズトレイン「TRAIN SUITE 四季島」に採用

地域本社 - 地域本部

Louvain-la-Neuve • ベルギー

アニッシュ工場 - 工場・事業所

Aniche • フランス

クデリチェ工場 - 工場・事業所

Chuderice • チェコ

タタバーニャ工場 - 工場・事業所

Tatabanya • ハンガリー

ロカセカ工場 - 工場・事業所

Roccasecca • イタリア

コシャリン工場 - 工場・事業所

Koszalin • ポーランド

スウプスク工場 - 工場・事業所

Slupsk • ポーランド

AGCガラス・ヨーロッパ セネフ工場 - 工場・事業所

Seneffe • ベルギー

ゴスリ テクノベーションセンター - 研究開発センター

Gosselies • ベルギー

AGC In-Vehicle Design Glass Europe GmbH - 工場・事業所

Landen (Frankfurt) • ドイツ

ケニトラ工場 - 工場・事業所

Kenitra • モロッコ

地域本社 - 地域本部

Farmington Hills, MI • アメリカ

オハイオ工場 - 工場・事業所

Bellefontaine, OH • アメリカ

ケンタッキー工場 - 工場・事業所

Elizabeth Town, KY • アメリカ

サンルイスポトシ工場 - 工場・事業所

San Luis Potosi • メキシコ

イプシランティ リサーチアンドディベロップメント - 研究開発センター

Ypsilanti, MI • アメリカ

グアラティンゲタ工場 - 工場・事業所

Guaratinguetá, State of São Paulo • ブラジル

本社

Tokyo • 日本

地域本社 - 地域本部

Tokyo • 日本

愛知工場 - 工場・事業所

Aichi • 日本

相模工場 - 工場・事業所

Kanagawa • 日本

AGCファブリテック - 工場・事業所

Tokyo • 日本

秦皇島工場 - 工場・事業所

Qinhuangdao, Hebei • 中国

仏山工場 - 工場・事業所

Foshan City, Guangdong Province • 中国

バンパコン工場 - 工場・事業所

Bangpakong • タイ

チカンペック工場 - 工場・事業所

Cikampek • インドネシア

ルワリ工場 - 工場・事業所

Rewari • インド

ルールキー工場 - 工場・事業所

Roorkee • インド

タロージャ工場 - 工場・事業所

Taloja • インド

チェンナイ工場 - 工場・事業所

Chennai • インド

パタン工場 - 工場・事業所

Patan • インド

蘇州R&Dセンター - 研究開発センター

Suzhou • 中国

商品開発センター - 研究開発センター

Kanagawa • 日本

AGCディスプレイグラス米沢 - 工場・事業所

Yamagata • 日本

AGC 横浜テクニカルセンター - 研究開発センター

Kanagawa • 日本

蘇州工場 - 工場・事業所

Suzhou • 中国

ビジョン

近年、「CASE」「MaaS」と呼ばれる新しい領域で技術革新が進み、クルマや移動の概念が大きく変わろうとする中、より安全に快適に移動できることが望まれています。一方で、CO2排出量削減など地球環境問題への対応が喫緊の課題となっています。

この環境に対応すべく、AGCオートモーティブは「モビリティ」を戦略事業と位置づけながら、「安全」「快適」で「つながる」モビリティ社会の実現に貢献する独自の製品・ソリューションを創出します。

また、CO2排出量低減に寄与するエコな製品・ソリューションの創出に加え、カーボンニュートラルに向けた製造プロセスの改善・開発にも取り組み、サステナブルな社会の実現に貢献します。

竹川 善雄

そして、AGCグループの一員として、企業理念“Look Beyond”に示す私たちのパーパス「AGC、いつも世界の大事な一部 〜独自の素材・ソリューションで、いつもどこかで世界中の人々の暮らしを支えます〜」の実現のため、飽くなき革新を追求し、ブランドステートメント“Your Dreams, Our Challenge”のもと、人々の想いの先、夢の実現に挑んでいきます。

Jean-Marc Meunier

大谷 啓之

Michael Antonucci

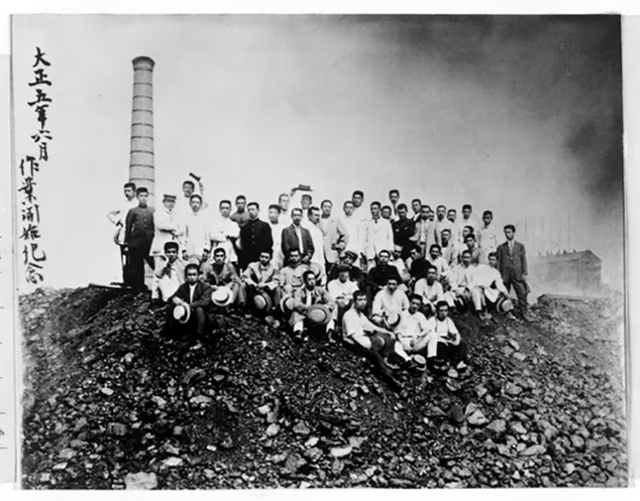

ヒストリー

設立

1907年、岩崎俊彌が旭硝子株式会社(現AGC株式会社)を設立。日本で初めて板ガラスの工業化に成功。岩崎俊彌の「易きになじまず難きにつく」という言葉は、時を超えて継承され、AGCグループの飛躍の原動力になっている。

自動車ガラス事業に進出

1956年、日本で自動車ガラス事業に進出。1970年に愛知工場、1972年には相模工場を設立した。

東南アジアで事業展開。生産技術開発により大量生産を可能に

東南アジアでの日系自動車企業の製造拠点新設と拡張の活発化に合わせ、1974年にタイ・セーフティガラス社(現AGCオートモーティブ・タイランド社)、1976年にはインドネシアにPTアサヒマス板硝子社を設立。また、業界初のガス炉を日本の工場に導入し、自動車用強化ガラスの大量生産を可能にした。

欧州、インド、北米で事業展開

1981年、AGCはガラス製造技術に秀でていたベルギーのグラバーベル社を買収。常に世界市場を視野に入れる伝統的な経営精神を受け継ぎながら、欧州内で積極的に事業展開。グラバーベル社の更なる成長にも貢献し、市場を活発化した。

1985年にはインドに旭インディア安全硝子株式会社(現旭インディア硝子株式会社)を設立し、事業を開始。

また同年、アメリカ最大の板ガラスメーカーと合弁でオハイオ州ベルフォンテンにAPテクノグラス社(現AGCオートモーティブ・アメリカ社)を設立。1986年にオハイオ工場、1989年にケンタッキー工場で生産を開始し、自動車用ガラス生産を通じて地域発展にも貢献した。

中国で事業展開、欧州で更なる事業拡大

1995年、中国の秦皇島海燕安全玻璃社(現艾杰旭汽车玻璃(秦皇島)有限公司)に資本参加。

一方、欧州では更なる事業拡大のため、1990年にチェコ共和国のSklo Union社を買収。1992年にはベルギーのSplintex社で合わせガラスの生産を開始。1997年にはロシアのBor Glassworks社に資本参加。更に1998年にはヨーロッパ企業の買収により、フランスとイタリアで事業を拡大した。

真のグローバル企業へと転換

2000年代、AGCは本格的にグローバル企業になるため様々な変革に取り組む。2002年にカンパニー制を導入し、グローバルマネジメント体制をスタート。2003年に自動車ガラス事業ブランドをAGCオートモーティブにグローバルで統一し、2007年にはAGCのグループブランドをAGCに統一。そして創立110周年を迎えた2018年、グローバルグループ一体経営を更に進化させるため、旭硝子株式会社からAGC株式会社に社名を変更した。

また、急拡大する中国の自動車市場に合わせて、2003年に中国の秦皇島海燕安全玻璃社(現艾杰旭汽车玻璃(秦皇島)有限公司)を子会社化し、秦皇島工場の生産能力を強化。2005年にAGCオートモーティブ・ハンガリー社で生産を開始。そして2008年には中国2番目の工場となる仏山工場でも生産を開始した。

新興諸国で事業展開 、モビリティ時代へ向けて新たな市場創造

2014年にブラジルのグアランティンゲタ工場、2016年にメキシコのサンルイスポトシ工場、そして2019年にはモロッコのケニトラ工場で生産を開始。一方、中国では2015年に3番目の工場として蘇州工場で生産を開始し、秦皇島、仏山拠点との一体運営を加速。また、自動車用補修ガラス事業を強化するため、2015年にポーランドのNordGlass社(現AGCオートモーティブ・ポーランド社) を買収した。

一方、2010年代、車は「つながるクルマ」へと進化し、ICT(Information and Communication Technology)化が加速。その変化に対応するため、2013年にAGCの関連会社であるAGCディスプレイグラス米沢で平面形状タイプの車載ディスプレイ用カバーガラスの生産を開始。2017年には京浜工場で世界初の3次元車載ディスプレイ用カバーガラスの生産を開始した。

また、V2X(Vehicle to Everything)の実現を見据え、2018年に「車両ガラス設置型5Gアンテナ」の開発に成功。2019年には自動車用ガラスアンテナの開発拠点となる電波暗室をベルギー・ゴスリーに建設した。

世界で初めて三次元曲面形状の車載ディスプレイ用カバーガラスを量産開始

AGC、自動車用ガラスアンテナの開発体制をグローバル3 極で構築

モビリティ社会の実現に貢献する高付加価値製品の開発を強化

AGCオートモーティブは「モビリティ」領域を戦略事業の一つと位置付けて、特にAGCグループの強みを発揮できる3分野:ディスプレイ・アンテナ・センサーの製品やソリューションの開発に注力。安全性や快適性を備えたモビリティ社会の実現に貢献する高付加価値製品の開発を更に強化。

調光ガラスDigital Curtain®DXが トヨタ自動車株式会社新型ハリアーに世界初採用

量産車向け曲面 OLED ディスプレイのカバーガラスとして世界初。大型・曲面車載ディスプレイ用カバーガラスがキャデラックに採用

サステナブルなモビリティ社会の実現に向けて

AGCオートモーティブはサステイナブルなモビリティ社会の実現をリードするため、独自の高付加価値製品とソリューションを開発し続けている。

中国の蘇州工場で大型3D・複雑形状の車載ディスプレイ用カバーガラスの生産開始

Low-eコート付き調光パノラマルーフがトヨタ自動車株式会社 LEXUS初のBEV専用モデル"RZ"に採用

調光ガラス Digital Curtain®がトヨタ自動車株式会社の"センチュリー"に採用

ニュース

2024年12月

•

ニュース

CES2025に出展

次世代モビリティ向け新製品を多数展示

次世代モビリティ向け新製品を多数展示

2024年9月

•

トピックス

AGC の車載ディスプレイ用加飾カバーガラスが

車内インテリアにもたらす新たな世界観

車内インテリアにもたらす新たな世界観

2024年1月

•

トピックス

AGC CES2024 ダイジェスト

2024年1月

•

ニュース

モビリティ社会をドライブするAGC

ジャパンモビリティショーで披露した最新技術と展望

ジャパンモビリティショーで披露した最新技術と展望

2023年12月

•

ニュース

AGC、「CES2024」に出展

-世界初公開を含む次世代モビリティに対応した最先端ソリューションを展示-

-世界初公開を含む次世代モビリティに対応した最先端ソリューションを展示-

2023年11月

•

トピックス

自動運転車の“眼”を高精度な状態に保つ

LiDARを保護しながら、パフォーマンスをサポートする

素材ソリューション

LiDARを保護しながら、パフォーマンスをサポートする

素材ソリューション

2023年11月

•

トピックス

次世代モビリティ市場創出をけん引する素材⾰命

2023年10月

•

トピックス

車載ディスプレイ用カバーガラス

「動く居住空間」となる 次世代自動車の価値を向上

「動く居住空間」となる 次世代自動車の価値を向上

2023年9月

•

ニュース

AGCの調光ガラス Digital Curtain®が

トヨタ自動車株式会社の「センチュリー」に採用

トヨタ自動車株式会社の「センチュリー」に採用

2023年7月

•

トピックス

高性能と意匠性を兼ね備える

AGCの5G通信対応ガラスアンテナ

AGCの5G通信対応ガラスアンテナ

2023年6月

•

トピックス

FIRカメラ対応フロントガラスで

夜間の歩行者交通事故ゼロに

挑戦するAGC

夜間の歩行者交通事故ゼロに

挑戦するAGC

2023年1月

•

トピックス

次世代モビリティの未来を指し示す

LEXUS×AGCの挑戦

LEXUS×AGCの挑戦

2022年12月

•

ニュース

AGC、「CES2023」で次世代モビリティを実現する製品・技術を展示

2022年5月

•

ニュース

AGCのLow-Eコート付き調光パノラマルーフが トヨタ自動車株式会社 LEXUS初のBEV専用モデル「RZ」に採用

2022年4月

•

ニュース

AGC、国際ガラス年 2022 特別企画展「ガラスの正体」を開催

2022年3月

•

ニュース

AGC、本田技研工業より優良感謝賞 「サステナビリティ部門」 を受賞

2022年1月

•

ニュース

AGC、「国際ガラス年2022」に協賛

2021年9月

•

ニュース

AGC 横浜テクニカルセンターのオープニングセレモニーを開催 - 社内外をシームレスにつなぐ新研究開発体制スタート -

2021年3月

•

ニュース

AGCのガラス製透明スクリーン Glascene®が車窓モビリティサイネージサービスに採用

2021年1月

•

ニュース

AGCの大型・曲面車載ディスプレイ用カバーガラスが キャデラックの新型「エスカレード」に採用

2020年6月

•

ニュース

AGCの調光ガラスWONDERLITE®Dxが トヨタ自動車株式会社新型ハリアーに世界初採用

2019年9月

•

ニュース

AGCの車載ディスプレイ用カバーガラスがLEXUSの新型「RX」に採用

2019年5月

•

ニュース

世界初、28GHz帯に対応する5G端末向けのガラスアンテナで通信に成功

2019年3月

•

ニュース

AGC、自動車用ガラスアンテナの開発体制をグローバル3 極で構築

2017年10月

•

ニュース

AGC旭硝子の切子調ガラスオーナメントが トヨタ自動車株式会社LEXUSの新型「LS」に採用

2017年9月

•

ニュース

AGC旭硝子の曲面形状の車載ディスプレイ用カバーガラスを搭載した世界初の量産車が登場

2017年6月

•

ニュース

鉄道用ガラスが新たな寝台列車「TWILIGHT EXPRESS 瑞風(みずかぜ)」に採用

2017年5月

•

ニュース

AGC旭硝子、世界で初めて三次元曲面形状の車載ディスプレイ用カバーガラスを量産開始

2017年5月

•

ニュース

AGC旭硝子の「WONDERLITE®」がクルーズトレイン「TRAIN SUITE 四季島」に採用

2016年8月

•

ニュース

AGC旭硝⼦、北アフリカへ初進出

2016年3月

•

ニュース

AGC 旭硝子、車載ディスプレイ用カバーガラスの供給体制を拡充 ―業界のパイオニアとして、旺盛な需要に対応―

2016年3月

•

ニュース

AGC旭硝⼦がブラジル第2 フロート⼯場を新設 - ガラス⽣産能⼒を 2.4 倍に増強

2016年3月

•

ニュース

AGC旭硝子、中国蘇州市の生産子会社の社名を変更 ―中国・自動車用ガラス事業の三拠点一体運営を加速

2015年12月

•

ニュース

世界初! 米国皮膚がん財団認証を自動車用窓ガラス全方位で取得 「UVベールPremium Privashield™」で認証取得

2015年11月

•

ニュース

世界初!全周99%UVカットを実現 「UVベール Premium Privashield™」の販売を開始

2015年4月

•

ニュース

AGC、欧州での自動車用補修ガラス事業を強化 ポーランドのNordGlass社を買収

2015年3月

•

ニュース

AGC旭硝子の鉄道用安全ガラスが北陸新幹線のすべての車両に搭載 - 祝・北陸新幹線開業 -

2015年3月

•

ニュース

AGC 旭硝子が「ミラノ国際博覧会」の日本館に協賛 ― 多彩なガラスが日本館の演出に貢献 ―

2015年2月

•

ニュース

AGC 旭硝子が世界最大規模のデザインの祭典「ミラノサローネ」に初出展

2014年12月

•

ニュース

世界初のガラスベンチルーフによるグローバルブランディング・プロジェクトが 「PRアワードグランプリ」コーポレート・コミュニケーション部門の最優秀賞を受賞

2014年9月

•

ニュース

AGCの調光ガラスWONDERLITE® が欧州高級車のガラスルーフに採用 特殊コーティングと組み合わせた大型調光ガラスで、快適性の向上と省エネに貢献

2014年6月

•

ニュース

メキシコにて自動車用ガラス新工場の起工式を実施

2014年5月

•

ニュース

0.05ミリ厚のガラス“SPOOL® ”のロール巻きに成功 フロート法による世界最薄ガラスで幅1,150ミリ、長さ100メートルを実現

2014年4月

•

ニュース

化学強化用特殊ガラスDragontrail® の採用実績が37ブランドに拡大 -強度向上新硝材 Dragontrail○R X で更なる拡販へ-

お問い合わせ

製品・ソリューション

採用

ガラス交換

その他

製品・ソリューション

Mobility and Automotive glass

Special glass for trains & industrial vehicles

AGCオートモーティブ・ヨーロッパ社

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

AGC Automotive Europe

+32-2-409-30-00

AGCガラスブラジル社

Brazil

Estrada Municipal Fazenda São Pedro

500 - Jardim Vista Alegre, City of Guaratinguetá

State of São Paulo, 12523-671, Brazil

500 - Jardim Vista Alegre, City of Guaratinguetá

State of São Paulo, 12523-671, Brazil

+55-12-3127-7100

https://agcbrasil.com/vidros-automotivos/

AGC株式会社 オートモーティブカンパニー

Japan

100-8405 東京都千代田区丸の内1-5-1

AGCオートモーティブ・アメリカ社

United States of America

34505 W. 12 Mile Road, Suite 300

Farmington Hills, MI 48331, USA

Farmington Hills, MI 48331, USA

AGC Automotive

+1-248-522-9300

AGCオートモーティブ・ヨーロッパ社

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

+32-2-409-30-00

AGC株式会社 オートモーティブカンパニー

Japan

100-8405 東京都千代田区丸の内1-5-1

AGCオートモーティブ・ヨーロッパ社

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

+32-2-409-30-00

AGCオートモーティブ・ヨーロッパ社

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

+32-2-409-30-00

ガラス交換

AGCオートモーティブ・ヨーロッパ社

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

AGC Automotive Replacement Glass

See sales offices contacts hereunder

http://www.agc-arg.eu

AGC株式会社 オートモーティブカンパニー

Japan

100-8405 東京都千代田区丸の内1-5-1

AGCガラスブラジル社

Brazil

Estrada Municipal Fazenda São Pedro

500 - Jardim Vista Alegre, City of Guaratinguetá

State of São Paulo, 12523-671, Brazil

500 - Jardim Vista Alegre, City of Guaratinguetá

State of São Paulo, 12523-671, Brazil

+55-12-3127-7100

https://agcbrasil.com/vidros-automotivos/

AGCオートモーティブ・アメリカ社

United States of America

4000 Gantz Road, Suite A

Grove City, Ohio 43123, USA

Grove City, Ohio 43123, USA

その他

AGCオートモーティブ・ヨーロッパ社

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

AGC Automotive Europe

+32-2-409-30-00

AGCガラスブラジル社

Brazil

Estrada Municipal Fazenda São Pedro

500 - Jardim Vista Alegre, City of Guaratinguetá

State of São Paulo, 12523-671, Brazil

500 - Jardim Vista Alegre, City of Guaratinguetá

State of São Paulo, 12523-671, Brazil

+55-12-3127-7100

https://agcbrasil.com/vidros-automotivos/

AGC株式会社 オートモーティブカンパニー

Japan

100-8405 東京都千代田区丸の内1-5-1

AGCオートモーティブ・アメリカ社

United States of America

34505 W. 12 Mile Road, Suite 300

Farmington Hills, MI 48331, USA

Farmington Hills, MI 48331, USA

AGC Automotive

+1-248-522-9300

AGCオートモーティブ・ヨーロッパ社

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

+32-2-409-30-00

AGCオートモーティブ・ヨーロッパ社

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

+32-2-409-30-00

AGCオートモーティブ・ヨーロッパ社

Belgium

Avenue Jean Monnet 4

1348 Louvain-la-Neuve, Belgium

1348 Louvain-la-Neuve, Belgium

+32-2-409-30-00

採用情報

Our Vision on Human Governance

At AGC Automotive Europe, our vision of human governance is based on taking human factors into account throughout any decision-making process. This human governance in turn leads to stronger management of the company.

It is based on full commitment to this course by all managers and is backed up by firm principles such as:

In operation, we view human development as a three-way partnership: between people and their aspirations, the business and its requirements, and human resources and their support forces.

Finally, it expresses our determination to build a company in which personal fulfilment leads to excellence.

Well-being

AGC Automotive Europe places the Well-Being of its staff at the center of their concerns and promotes a policy which unites the balance between company goals and Well-being at work.

People development

At AGC Automotive Europe, our people are our strength. Every person is unique and deserves the best development opportunities. We strive to give everyone an opportunity to grow as an employee and as a person.

Diversity, equity & inclusion

Today, the world is characterized by uncertainty and volatility, enhanced by shifting technology. We are not all equal in front of these challenges. It is our responsibility at AGC Automotive Europe to contribute to a successful SOCIAL TRANSITION. We want to secure a SAFE workplace for everyone, improve WELL-BEING in our jobs and DEVELOP our people. We aim for DIVERSITY, EQUITY and INCLUSION.

Environment

Career opportunities with AGC Europe

Have a look at our current job openings in our European Career Website!

If you wish more than automotive opportunities, select “display all” area & location.

採用情報

Brand statements

“Your Dreams, Our Challenge”

The AGC Group’s business began more than 100 years ago with the ambitious aim of manufacturing the country’s first flat glass to help people’s daily life and industrial development.

Our unique materials, solutions and reliable partnerships have facilitated leading innovations across diverse industries and markets. Today, by working with others to combine knowledge and advanced technology, we help make ever greater achievements possible, and bring bolder ideas to life.

Our brand statement

Learn more about careers

Compensation & benefits

Competitive compensation

You'll be recognized with competitive compensation to provide financial wellness for you and your family.

Health

Medical, Dental, Vision and Prescription Drug benefits are available for you and your family. Professional coaching is available to assist you in making the right health care choices 24/7.

Employee Assistance Program provides prompt, confidential support with a range of personal and family issues that may affect all of us from time to time.

Well-being

We recognize that time away from work is essential for our associates to refresh and renew. Paid vacation and holidays are offered to our associates.

Dozens of discounts with great merchants and big brands will be offered to our associates to help the associate's well-being.

Financial security

Company -paid Life Insurnace and Accidental Death & Dismemberment with the option to enroll in Supplemental Life and Accidental Death & Dismemberment Insuranec helps provide financial support for you and your family during difficult times.

Our 401(K) plan helps you meet one of life's most important goals - financial security in retirement.

Environment

Find jobs

Production Supervisor,

Elizabethtown, KY

SAP/MRP Specialist

Elizabethtown, KY

Account Manager (Corporate)

Farmington Hills, MI

Account Manager- Business Development

Farmington Hills, MI

Process Technology Engineer

Farmington Hills, MI

Production Specialist

Elizabethtown, KY

Quality Engineer

Elizabethtown, KY

Process Engineer

Elizabethtown, KY

Tooling Maintenance Associate

Elizabethtown, KY

Production Associate

Elizabethtown, KY

Maintenance Associate

Elizabethtown, KY

採用情報

サイトのご利用について

著作権・商標権等について

本サイト上のコンテンツ(文書、写真、イラスト、動画、音声、プログラム等)は、AGC株式会社(以下「当社」といいます)および第三者が有する著作権により保護されており、当社に無断で転用・複製することは出来ません。

本サイトで使用しているロゴは当社の商標ですので当社に無断で転用・複製することは出来ません。

免責事項

当社は、本サイトに掲載する情報が最新かつ正確な情報になるよう細心の注意を払っておりますが、個別に特段の明示がない限り本サイトのコンテンツの妥当性や正確性等について保証するものではなく、一切の責任を負いません

本サイトのコンテンツやURLは予告なしに変更、中断または中止されることがありますので、あらかじめご了承願います。当社は、理由のいかんにかかわらず、本サイトのコンテンツの変更および本サイトの運用の中断または中止によって生じるいかなる損害についても責任を負うものではありません。

特に投資家情報に関しては投資家判断の参考となる情報提供を目的とするものであり、当社株式の購入や売却を勧誘するものではありません。投資に関する最終決定は利用者ご自身のご判断において行われるようお願い致します。

リンクについて

別途当社の合意がない限り、本サイトへリンクを張ることはお控えください。当社に無断で本サイトへリンクを張ったことで貴社または貴方が損害を被ったとしても、当社は一切責任を負いません。

本サイトから本サイト以外のサイト(以下「他サイト」)へリンクが張られている場合には、当社が他サイトの利用や掲載内容等を推奨することを意味するものではなく、他サイトまたはその運営者と当社との間に何ら提携関係等特段の関係があることを意味するものではありません。

本サイトへリンクを張っている他サイトは、それぞれ当社とは異なる他サイトの開設者の責任において管理運営されております。従いまして、他サイトの利用にあたりましては他サイトの利用条件に従ってください。当社は、他サイトの内容につき何ら保証するものではなく、またその利用に伴う一切の損害について責任を負いません。

プライバシーポリシー

個人情報保護方針

AGCグループ(AGC株式会社及びその子会社)の各法人(以下、AGCグループと称します)は、お客様、取引関係者及び従業員等、AGCの業務と関わりのあるすべての関係者の氏名、住所、電話番号等の個人を識別できる情報(以下併せて「個人情報」と称します)について、その適切な保護が非常に重要であると認識しています。

AGCグループは、常に社会的責任を認識し、プライバシーの保護、個人情報に関する法規制等を遵守し、事業活動を行うために、以下の基本方針を制定します。

AGCグループは、公正かつ適法な方法で個人情報を取得、利用および提供します。

利用範囲と目的

個人情報の取得に際しては、利用目的等を特定します。 取得した個人情報は、利用目的の範囲内で、業務に必要な範囲に限定して利用します。

個人情報の取得に際しては、利用目的等を特定します。 取得した個人情報は、利用目的の範囲内で、業務に必要な範囲に限定して利用します。

本人同意

あらかじめ特定した範囲を超えて個人情報を利用する必要が生じた場合には、法令により許される場合を除き、その利用について、情報主体(個人情報の本人様)の同意を得るものとします。

あらかじめ特定した範囲を超えて個人情報を利用する必要が生じた場合には、法令により許される場合を除き、その利用について、情報主体(個人情報の本人様)の同意を得るものとします。

安全管理措置

個人情報を取り扱うにあたり、管理するための組織と体制を設置し、個人情報への不正アクセス、個人情報の紛失、改ざん、漏洩等が発生することのないように、適切な管理に努めます。 また、継続的に見直しを行い、安全管理措置の強化と改善を推進します。

個人情報を取り扱うにあたり、管理するための組織と体制を設置し、個人情報への不正アクセス、個人情報の紛失、改ざん、漏洩等が発生することのないように、適切な管理に努めます。 また、継続的に見直しを行い、安全管理措置の強化と改善を推進します。

第三者への提供

情報主体の同意を得た場合または法令により許された場合を除き、個人情報を第三者に提供しません。また、個人情報を第三者に提供する場合には、契約等により個人情報の管理を義務付け、その第三者からの漏洩、再提供の防止などに努めます。

情報主体の同意を得た場合または法令により許された場合を除き、個人情報を第三者に提供しません。また、個人情報を第三者に提供する場合には、契約等により個人情報の管理を義務付け、その第三者からの漏洩、再提供の防止などに努めます。

AGCグループは、情報主体が自己の個人情報について、開示、訂正、追加または削除を希望される場合には、法令及び規則に従い、すみやかに対応します。

AGCグループは、個人情報の保護に関する各種法令、規則等を遵守するとともに、上記の項目における取り組みを継続的に見直し、その改善に努めます。

AGCグループは、この方針を、AGCグループの役員、従業員(嘱託社員、人材派遣社員等を含む)および関係者に周知徹底することによって、一人ひとりがその重要性を認識し、実行する風土づくりに努めます。

個人情報の収集目的について

AGCグループは、原則として、以下の目的で個人情報を利用します。(なお、個別に利用目的が明示されている場合は、その利用目的に従った利用を行います。)それ以外の目的で利用する場合は、個人情報をご提供いただく際に、予めその旨を明示します。

お問い合わせ・ご要望や資料請求への回答と対応

AGCグループの製品・サービスおよび関連情報の提供

AGCグループの製品・サービスの利用に係る状況、ニーズなどの調査、改善

AGCグループの製品の営業、販売、サービスの提供等に関する業務

AGCグループの事業活動において必要な業務連絡

個人情報の共有について

AGCグループは、AGCグループ各社との間で個人情報を下表の通り共同利用します。

| 共同利用する者の範囲 | AGCグループ各社 詳細は こちらをご参照ください |

| 共同して利用する個人情報の項目 | 氏名、住所、電話番号、FAX番号、メールアドレス、勤務先(所属部署、役職、お問い合わせ・お取引内容等) |

| 共同する者の利用目的 | 上記「個人情報の収集目的について」記載の目的 |

| 管理について責任を有する者 | AGC株式会社 住所および代表者氏名はこちらをご参照ください |

個人情報の第三者提供について

以下のいずれかに該当する場合を除き、ご本人から取得した個人情報を第三者へ開示または提供しません。

ご本人の同意がある場合

利用目的の達成に必要な範囲内において業務委託先(再委託先を含みます。)に個人情報の取扱いの全部または一部を委託することに伴って当該個人情報を提供する場合

上記の「共同利用する者の範囲」に掲げる者に対して提供する場合

法令に基づき開示・提供を求められた場合

人の生命、身体または財産の保護のために必要な場合であって、ご本人の同意を得ることが困難である場合

国または地方公共団体等が公的な事務を実施する上で協力する必要がある場合であって、ご本人の同意を得ることにより当該事務の遂行に支障を及ぼすおそれがある場合

個人情報の安全管理措置について

個人情報を取り扱うにあたり、管理するための組織と体制を設置し、個人情報への不正アクセス、個人情報の紛失、改ざん、漏洩等が発生することのないように、適切な安全管理措置に努めます。 その主な内容は以下のとおりです。

個人情報保護方針の策定

個人情報の適正な取扱いの確保のため、各種法令、規則等の遵守、個人情報の請求及び問合せ窓口等について本個人情報保護方針、内規、マニュアルを策定しています。

個人情報の取扱いに係る規律の整備

個人情報の取得、利用、保存、提供、削除・廃棄等の段階ごとに、取扱方法等について個人情報保護管理規程を定めています。

また、以下の個人情報の安全管理措置について、定期的に点検を実施しています。

組織的安全管理措置

個人情報の取扱いに関する責任者を設置するとともに、個人情報を取り扱う従業員及び当該従業員が取扱う個人情報の範囲を明確化し、個人情報保護法や個人情報保護管理規程に違反している事実を把握した場合の報告連絡体制を整備しています。

物理的安全管理措置

個人情報を取扱う区域において、従業員の入退室管理及び持ち込む機器等の制限を行うとともに、権原を有しない者による個人情報の閲覧を防止する措置を実施しています。

個人情報を取り扱う機器、電子媒体及び書類等の盗難又は紛失等を防止するための措置を講じています。

技術的安全管理措置

アクセス制御を実施して、担当者及び取り扱う個人情報データベース等の範囲を限定しています。

個人情報を取り扱う情報システムを外部からの不正アクセス又は不正ソフトウェアから保護する仕組みを導入しています。

人的安全管理措置

個人情報の取扱いに関する留意事項について、従業員に教育・Eラーニングを実施しています。

外的環境の把握

当社は、外国において個人情報を取り扱うにあたっては、定期的に当該国の個人情報保護制度に関する情報を収集し把握した上で、安全管理措置を講じています。

情報主体の権利

個人情報のご本人には、各国の個人情報保護に関する法令に則った権利があります。

個人情報の開示・訂正・削除請求に関する手続き

ご提供頂いた個人情報に関する各請求手続きの概要は次のとおりです。なお、詳しい内容については、個人情報を提供されたサービス部門にお問い合わせ下さい。

※窓口が不明な場合は、本社代表電話までお問い合わせください。

ご請求について

請求を希望される場合には、個人情報を提供されたサービス部門(ウェブの場合はウェブサイトの管理部門)にお問い合わせ下さい。請求のための所定用紙をお送りいたしますので、ご記入のうえ郵送にてご提出下さい。なお、個人情報の漏洩を防ぐため、個人情報のご本人からのご請求にのみ、対応させていただきます。(ただし、法定代理人はのぞく。)

請求を希望される場合には、個人情報を提供されたサービス部門(ウェブの場合はウェブサイトの管理部門)にお問い合わせ下さい。請求のための所定用紙をお送りいたしますので、ご記入のうえ郵送にてご提出下さい。なお、個人情報の漏洩を防ぐため、個人情報のご本人からのご請求にのみ、対応させていただきます。(ただし、法定代理人はのぞく。)

ご提出頂くもの

請求者がご本人であることを確認するため、所定の請求用紙に加え、運転免許証、住民票の写しのうち1通をあわせてご提出ください。

請求者がご本人であることを確認するため、所定の請求用紙に加え、運転免許証、住民票の写しのうち1通をあわせてご提出ください。

ご回答方法

お受けしたご請求については、登録内容の確認を行い、後日、ご本人に対し、直接、郵送にて、ご回答申し上げます。 請求がご本人からなされているとの確認ができない場合、ご回答を差し控えさせていただくこともございますので、ご了承ください。また、迅速にご回答差し上げるよう努めますが、回答の正確性を確保するため、ご回答までにお時間がかかることもございます。予めご了承ください。

お受けしたご請求については、登録内容の確認を行い、後日、ご本人に対し、直接、郵送にて、ご回答申し上げます。 請求がご本人からなされているとの確認ができない場合、ご回答を差し控えさせていただくこともございますので、ご了承ください。また、迅速にご回答差し上げるよう努めますが、回答の正確性を確保するため、ご回答までにお時間がかかることもございます。予めご了承ください。

個人情報に関するお問い合わせ

個人情報に関するその他のお問い合わせについては、個人情報を提供されたサービス部門にお問い合わせください。

※窓口が不明な場合は、本社代表電話までお問い合わせください。

アクセスログについて

本ウェブサイトでは、アクセスされた方の情報をアクセスログという形で記録していますが、アクセスログは個人を特定できる情報を含むものではありません。本ウェブサイトでは、利用状況に関する統計・分析やお客様への情報提供、その他サイトの利便向上性向上のために情報を採取しております。

リンク先における個人情報の保護について

本ウェブサイトには当社及び当社グループ各社以外のウェブサイトへのリンクが含まれている場合があります。当社は当社及び当社グループ各社以外のウェブサイトにおける個人情報の保護及びコンテンツに関する責任は一切負うことはできません。

運営者

AGC株式会社オートモーティブカンパニー

〒100-8405 東京都千代田区丸の内1-5-1

お問い合わせはこちらのフォームよりお寄せ下さい。

サイトマップ

製品・ソリューション

製品・ソリューション

技術開発

事業内容

モビリティ

自動車用ガラス

自動車用補修ガラス

輸送機器・産業車両用ガラス

グローバルな生産体制

企業情報

ビジョン

ヒストリー

企業理念

事業概要

研究開発

サステナビリティ

株主・投資家情報

ニュース

お問い合わせ

採用情報

ヨーロッパ

北米

日本

サイトのご利用について

プライバシーポリシー

AGC Automotive Europe quality

AGC Automotive Americas documents

運営者

Search

車載ディスプレイ用カバーガラス

車載ディスプレイ用

カバーガラスとは

カバーガラスとは

AGCの化学強化用特殊ガラス Dragontrail®を採用し、自動車用内装材として求められる高い安全性を確保したカバーガラスです。

特長

01

デザイン性向上に寄与

ガラス自体のもつ質感によって上質なインテリアにマッチし、一体感あるダッシュボードを実現する等、自動車の内装デザイン性向上に寄与します。

02

高い視認性と操作性

AGCの独自技術である映り込みを抑え指紋をつきにくくする等の光学成膜や加飾印刷技術によって、ディスプレイの視認性や操作性の向上に寄与します。

03

業界トップの技術と生産体制

2013年に世界で初めて、平面形状タイプの車載ディスプレイ用カバーガラスを素板から加工まで一貫生産する体制を整え、提供を開始。2017年からは、曲面形状タイプも生産・提供を開始しました。これまでに100車種以上2,500万枚以上の出荷実績を持ちます。

部位

ギャラリー

車窓ディスプレイ

車窓ディスプレイとは

2 枚のガラスの間に特殊なスクリーンフィルムを挟んだ合わせガラスで、プロジェクターの映像をガラス上に投影することができます。

特長

01

優れた視認性と透過性の両立

映像を投影していない時は透明な窓ガラスですが、投影時は高コントラストでクリアな映像をガラスに投影します。

02

高い安全性と耐久性

自動車用窓ガラスとして求められる安全性と耐久性を確保しています。

03

想定ユースケース(車外向け)

例えば、モビリティの窓に広告を投影したり、歩行者や他のモビリティにメッセージを表示したり、モビリティの窓が情報発信源として機能する、そんな未来を想定しています。

04

想定ユースケース(車内向け)

例えば、観光用途モビリティの窓におすすめスポットの映像を投影しながら運行することで、ワクワクする移動体験を提供できる、そんな未来を想定しています。

部位

ギャラリー

併せてご覧下さい

調光ガラス Digital Curtain®

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

黒セラ部投影HUD

(Black Band Display)

(Black Band Display)

黒セラ部投影HUDとは

フロントガラス下部の黒色印刷部分にHUD像を投影し、フロントガラス全幅をディスプレイ化することができます。AGCが独自に開発したコーティングを施すことで、通常は反射率の低いP偏光成分の反射率を向上させ、いかなる状況下でも視認可能なHUDを提供します。

特長

01

安全性が向上

表示が背景と近づくためドライバーの視線移動が減り、また目の焦点が合いやすくなることで疲労軽減と安全性向上に寄与します。

02

先進的でスタイリッシュなコックピットを実現

メータークラスターの代替となり、先進的且つすっきりしたコックピット、車内空間を実現します。

03

偏光サングラス着用時でも視認可能なHUDを実現

通常反射率の低いP偏光波の光の反射率を高めることによって、偏光サングラス着用時でも視認可能なHUDシステムを提供します。

04

効率的な情報取得による、ストレスの軽減を実現

ドライバーが視線を外さず、情報確認することを可能にし、情報をすぐに得られることでより迅速に適切な行動が可能になります。また必要な情報を簡単に得られることで運転中のストレス軽減が期待されます。

部位

ギャラリー

併せてご覧下さい

ヘッドアップディスプレイ

車窓ディスプレイ

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

LiDAR用カバーガラス Wideye®

LiDAR用カバーガラス Wideyeとは

センシングに用いられる波長領域に対応する特殊な赤外線透過ガラスです。

特長

01

自動運転の「目」を担うガラス

特殊な赤外線透過ガラスを用いて、LiDARセンサーと車体を統合するためのソリューションを提供します。このソリューションにより、センサーは昼夜問わず、的確に物体を捉えることが可能です。

02

優れた品質を提供

LiDARやカメラに求められる光学要件に準拠しており、センサーの精度や解像度を損なうことはありません。

03

車体デザインに寄与

ウィンドシールドやBピラーカバーガラス等の既存部位だけでなく、新たに設計される窓に対してもシームレスにセンサーと統合することができ、車体デザインを損なうことはありません。 お客様の設計要件やエンジニアリングのニーズに柔軟にお応えします。

04

センサーを保護し、安全性と快適性に寄与

飛び石や振動、雨、汚れ、霧、霜等からセンサーを保護し、安全性と快適性の向上に寄与します。

部位

ギャラリー

併せてご覧下さい

ヘッドアップディスプレイ

ガラスアンテナ

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

ガラスアンテナ

ガラスアンテナとは

ガラスとアンテナ(AM、FM、DTVなど)を一体化したガラスです。導電性インクをプリント焼付けでガラスに一体成型するプリントタイプや、フロントガラスにシールタイプのアンテナを封入するタイプがあります。

特長

01

優れた美観

アンテナがガラスと一体化して目立たず、美観を損なうことがありません。

02

他機能との組み合わせも可能

HUDや電熱システムなど他の機能と組み合わせることが可能です。

03

迅速なプロトタイピングが可能

高度なプロトタイピング技術により、迅速なサンプル提供を可能にします。

04

3極での支援体制

日本・米国・欧州の3極に電波暗室を持って開発体制を整えており、お客様をグローバルに支援します。

05

リードタイムを短縮

設計から開発、シミュレーション、製造までをトータルて担い、お客様のリードタイム短縮に貢献します。

部位

ギャラリー

5G通信対応ガラスアンテナ

5G通信対応ガラスアンテナとは

グローバルのLTE+5G-sub6の周波数に対応するアンテナシステムをフロントガラスやサイドガラス、リアガラス、ルーフガラスの中に組み込み、“分散配置”することにより通信の安定化と高速化が可能になります

特長

01

「分散配置」で安定した通信性を実現

車両ガラス上に複数のアンテナを分散配置する「分散配置アンテナ(DAS=Distributed Antenna System)」を適用することで、通信の安定化と高速化が可能になります。

02

車体のデザインに自然に溶け込む

ガラスに配置するアンテナシステムは薄い平面形状のため、車両のデザインを損なうことがありません。

03

遮熱・断熱性能との両立も実現

遮熱・断熱のために用いられる導電性膜のコーティングによって電波透過が阻害されないよう、FSS(Frequency Selective Surfaces=周波数選択表面)や周波数帯に応じた反射制御技術を駆使し、通信性と遮熱・断熱性を両立させることが可能です。

04

「基板タイプ」と「透明タイプ」をラインナップ

ガラスの黒セラ内に隠蔽可能な「基板タイプ」と、ガラスの可視エリアに適用可能な「透明タイプ」の2種類を取り揃えています。

05

Halo.Car社の「リモート操縦システム」に導入

AGCの5G通信ガラスアンテナは、5Gを経由した遠隔操作による無人配車・引き取りによるレンタカーサービスを提供する米国Halo.Car社の「リモート操縦システム」に導入されています。

部位

ギャラリー

併せてご覧下さい

ガラスアンテナ

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

FIRカメラ対応フロントガラス

FIRカメラ対応

フロントガラスとは

フロントガラスとは

フロントガラスの一部にFIR(遠赤外線)を透過する特殊材料を一体化することで、車室内への「可視カメラ・FIRカメラ 一体搭載」を可能にしたフロントガラスです。(開発中)

特長

01

高い位置にFIRカメラ搭載が可能

フロントグリル周辺にFIRカメラを搭載するのに比べ先行車や障害物の影響を受けづらく、長距離かつ広い視野で早期に物体の認識が可能になります。

02

ワイパー払拭範囲にFIRカメラ搭載が可能

雨天など悪天候時でもカメラ前面をクリーンに保ち、センシング機能を維持することができます。

03

可視カメラとFIRカメラの視差が少ない

可視カメラとFIRカメラの設置場所を近接させることで画像の重ね合わせが容易になり、センサーフュージョンに有利です。

04

夜間の歩行者検知による交通事故の低減に貢献

夜間のセンシング性能が大幅に向上し、歩行者検知による交通事故の低減に貢献します。

部位

ギャラリー

併せてご覧下さい

LiDAR用カバーガラス Wideye®

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

調光ガラス Digital Curtain®

調光ガラスとは

2枚のガラスの間に挟み込んだフィルム中の特殊材料の分散配向を電圧でコントロールすることで、調光モードと透過モードを瞬時に切り替えられるガラスです。

特長

01

光の透過を自在にコントロール

スイッチひとつで、ガラスから車内に入る光の透過率を自分好みに調整することができます。

02

サングラスをかけるような手軽さで、ガラスの色を切替え

ほんの数秒で、簡単にガラスを透明から不透明な暗色に切り替えることができます。

03

瞬時にプライバシー性を確保

ガラスを不透明な暗色に切り替えることで、瞬時にプライバシーを確保することができます。

04

必要な部分だけ遮光できる、”デジタル・カーテン”

ガラスをゾーニングすることで、スイッチひとつでカーテンのように遮光したい部分だけを遮光することができます。

05

ニーズに合わせて調光パターンをカスタマイズ

車の仕様やニーズに合わせて、ガラスの色や光の透過率、切り替えパターンなどをカスタマイズすることができます。

部位

ギャラリー

併せてご覧下さい

赤外線カットガラス クールベール®

Low-eガラス

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

Low-eガラス

Low-eガラスとは

ガラスに特殊な金属コーティングを施したガラスです。高い遮熱・断熱性能を持ちます。

特長

01

夏は涼しく

夏は日射熱を遮り、涼しく快適な車内環境を実現します。

02

冬は暖かく

冬は車内の熱を外に逃しづらく、暖かく快適な車内環境を実現します。

03

環境負荷を低減

冷房負荷を低減し、燃費向上やEVの航続距離延長、CO2排出量低減に寄与します。

04

オープンエアでドライブを楽しく

従来のサンルーフ・シェードを無くし、常にオープンエアを楽しむことができます。シェードのコスト削減や重量削減、頭上スペースの確保にもつながります。

部位

ギャラリー

併せてご覧下さい

赤外線カットガラス クールベール®

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

透明導電膜付きウィンドシールド

透明導電膜付き

ウィンドシールドとは

ウィンドシールドとは

導電性を持った特殊なコートを施したガラスです。通電することでガラスを温めることができます。また、高い遮熱性能も持ちます。

特長

01

スイッチひとつで素早く融氷

スイッチひとつで、ガラスに積もった雪や氷を効率的に素早く融かします。

02

優れた防曇効果

ガラスの曇りを防ぎ、良好な視界を確保します。

03

夏の車内も快適に

車内温度上昇やハンドル温度上昇を抑制し、夏でも快適な車内環境を実現します。

04

ワイパー・ブレードの劣化を抑制

ワイパー・ブレードを長持ちさせます。

05

柔軟な組付けが可能

ワイパー、カメラ、センサーなどの限定されたエリアのみに電熱システムを組み込むことが可能です。

部位

ギャラリー

併せてご覧下さい

赤外線カットガラス クールベール®

Low-eガラス

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

導電ワイヤー封入ウィンドシールド

導電ワイヤー封入

ウィンドシールドとは

ウィンドシールドとは

2枚のガラスの間に挟んだ中間膜に、極めて細く目立たない導電ワイヤーを封入したガラスです。通電することでガラスを温めることができます。

特長

01

スイッチひとつで素早く融氷

スイッチひとつで、ガラスに積もった雪や氷を効率的に素早く融かします。

02

優れた防曇効果

ガラスの曇りを防ぎ、良好な視界を確保します。

03

柔軟な組付けが可能

ワイパー、カメラ、センサーなどの限定されたエリアのみに電熱システムを組み込むことが可能です。

部位

ギャラリー

併せてご覧下さい

透明導電膜付きウィンドシールド

合わせガラス LAMISAFE™

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

ヘッドアップディスプレイ

ヘッドアップディスプレイ

とは

とは

ドライバーの前面のガラスに、速度計やナビ情報等の運転に必要な情報を投影するガラスです。

特長

01

安全性が向上

運転中の視線移動や焦点調整が少なくなり、安全性が向上します。

02

利便性が向上

込み入った道路状況においても、カーナビだと視線を動かして情報を読み取る必要がありますが、ヘッドアップディスプレイであれば視線の先に情報が表示され、認識負荷も軽減されます。

部位

ギャラリー

併せてご覧下さい

車窓ディスプレイ

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

薄板合わせガラス

薄板合わせガラスとは

ウィンドシールド、サイドガラス、リアガラス等の板厚を薄くすることで、車両の軽量化に寄与するガラスです。

特長

01

CO2排出量削減に寄与

車両が軽量化されることで、燃費向上やCO2排出量の低減に寄与します。

02

EV航続距離に寄与

車両が軽量化されることで、EVの航続距離延長に寄与します。

03

優れた強度

通常のウインドシールドとほぼ同等の強度を持ちます。

04

優れた遮熱効果

通常のウインドシールドとほぼ同等の遮熱効果を持ちます。

部位

ギャラリー

併せてご覧下さい

強化ガラス TEMPERLITE™

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

遮音ガラス サウンドベール™

遮音ガラスとは

2枚のガラスの間に特殊な遮音膜を挟んだガラスです。車外から入り込む騒音の透過を低減します。

特長

01

静粛な車内空間を実現

静かで快適な車内環境を実現します。

02

衝撃物が貫通しにくい

2枚のガラスの間に挟んだ特殊な膜が強じんなので、飛び石や接触事故など前方からの衝撃物に対して貫通しにくい特性を持ちます。

03

盗難防止に効果的

2枚のガラスの間に挟んだ特殊な膜が強じんなので、飛び石や接触事故など前方からの衝撃物に対して貫通しにくい特性を持ちます。

部位

ギャラリー

併せてご覧下さい

薄板合わせガラス

透明導電膜付きウィンドシールド

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

赤外線カットガラス クールベール®

赤外線カットガラスとは

2枚のガラスの間に特殊な膜を挟むことにより、赤外線の中でも最もジリジリ感を感じさせる波長領域を大幅カットするガラスです。

特長

01

夏の車内も快適に

車内温度上昇やハンドル温度上昇を抑制し、夏でも快適な車内環境を実現します。

02

車内温度を低減

車内温度を低減することができます。

03

冷房効率を向上

エアコンによるクールダウンの時間を短縮します。

04

CO2排出量削減に寄与

冷房負荷が低減されることで、燃費向上やCO2排出量の低減に寄与します。

05

EV航続距離に寄与

冷房負荷が低減されることで、EVの航続距離延長に寄与します。

部位

ギャラリー

併せてご覧下さい

透明導電膜付きウィンドシールド

Low-eガラス

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

99%UVカットガラス

99%UVカットガラスとは

ガラスに紫外線を約99%カットする機能を持たせたガラスです。ウィンドシールド、サイドガラス、リアガラスに適用することができ、車の全方位から降り注ぐ紫外線をカットすることができます。

特長

01

紫外線から肌を守る

ドライバーや助手席の方だけでなく、後部座席の方の肌も紫外線から守ります。

02

暑さやジリジリ感を軽減

UVカット機能に加え、IRカット機能も搭載し、「車内が暑い」、「運転中に腕がジリジリする」 といったIRを原因とする不快感を解消します。

03

環境負荷を低減

暑さを和らげ、弱めのエアコン設定を可能にすることで、環境負荷低減に寄与します。

04

世界初の全方位UV99%カット

世界で初めて1)、ウィンドシールド、サイドガラス、リアガラスで約99%2)UVカットを実現しました。

1) 2015年11月現在 弊社調べ

2)弊社測定値。ISO9050基準

部位

ギャラリー

併せてご覧下さい

合わせガラス LAMISAFE™

プライバシーガラス マイベール™

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

プライバシーガラス マイベール™

プライバシーガラスとは

ガラスに着色成分を添加したガラスです。プライバシー性を確保するとともに、高い遮熱性を持ちます。

特長

01

スタイリッシュな外観を実現

上品な色合いの濃色ガラスで、洗練されたスタイリッシュな外観を実現します。

02

プライバシーを確保

外から車内が見えにくく、プライバシーを確保します。車上荒らしなどの盗難防止にも役立ちます。

03

太陽熱を低減

車内に入る日射熱を低減し、快適な車内環境を実現します。

04

環境負荷を低減

冷房負荷を低減し、燃費向上やCO2排出量の低減に寄与します。

05

眩しさを低減

車内に入る光の眩しさを低減し、快適な車内環境を実現します。

部位

ギャラリー

併せてご覧下さい

強化ガラス TEMPERLITE™

調光ガラス Digital Curtain®

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

ドア撥水ガラス ウェルビュー™

撥水ガラスとは

高い撥水性と耐久性を併せ持つフッ素系材料をコーティングし、雨天時の視認性を向上させるガラスです。

特長

01

泥ハネの付着も防止

コーティングの効果により、泥ハネの付着も防止します。

02

雪や氷も落としやすい

コーティングの効果により、窓ガラスに着いた雪や氷も落としやすくなります。

部位

ギャラリー

併せてご覧下さい

LiDAR用カバーガラス Wideye®

99%UVカットガラス

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

ピラー用カバーガラス

ピラー用カバーガラスとは

車のAピラー、Bピラー、Cピラーなどに施すことができるガラス製のカバーです。

特長

01

優れた耐久性

プラスチック製ピラーに比べ、優れた耐久性を持ちます。

02

デザイン性向上に寄与

ピラー部分の突起を無くし面一性を持たせることで、車体のデザイン性向上に寄与します。

03

コネクテッド機能の付加も可能

カメラやディスプレイ、アンテナ等の機能を組み込むこともできます。

部位

ギャラリー

併せてご覧下さい

LiDAR用カバーガラス Wideye®

ガラスアンテナ

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

モジュールアッシーウィンドウ

空力改善や遮音性向上に寄与

窓ガラス、モール、周辺の樹脂部品を一体成形することによって、空力を改善し、遮音性を向上させます。

特長

01

フラッシュサーフィス化に寄与

車体のフラッシュサーフィス化に寄与します。

02

カスタマイズが可能

モジュールはカスタマイズが可能で、ブラケットやカメラ、アンテナ等の機能と組み合わせることができます。

部位

ギャラリー

併せてご覧下さい

強化ガラス TEMPERLITE™

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

合わせガラス LAMISAFE™

合わせガラスとは

2枚のガラスの間に中間膜と呼ばれる特殊フィルムを挟んだガラスです。割れても破片が飛び散りにくい特性を持ちます。

特長

01

衝撃物が貫通しにくい

特殊フィルムが強じんなので、飛び石や接触事故など前方からの衝撃物に対して貫通しにくい特性を持ちます。

02

盗難防止に効果的

割れにくいため、車上荒らしなどの盗難防止に効果的です。

03

紫外線から肌を守る

紫外線をカットし、乗員の肌を守ります。

04

車外の騒音を低減

車外の騒音を低減し、静かで快適な車内環境を実現します。

部位

ギャラリー

併せてご覧下さい

遮音ガラス サウンドベール™

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

強化ガラス TEMPERLITE™

強化ガラスとは

ガラスを軟化点(約650℃)近くまで加熱し、表面を空気で均一に急冷することで強度を高めた特殊加工ガラスです。割れると瞬間的に破砕する特性を持ちます。

特長

01

一般板ガラスの3~5倍の強度

同じ厚さの板ガラスと比較し、3~5倍の強度を持ちます。

02

割れても安全

たとえガラスが割れても、細かい粒状に粉々に割れ、破片も鋭く尖っていないため、破片で大きな怪我をすることはほとんどありません。

03

化学強化により、軽量化も可能

ガラスに更に化学強化を施すことで、ガラスの強度は損なわずに板厚を薄くすることもでき、軽量化することができます。

部位

ギャラリー

併せてご覧下さい

プライバシーガラス マイベール™

99%UVカットガラス

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

高断熱ガラス

高断熱ガラスとは

高い断熱性を持った特殊なコートを施したガラスです。快適な車内環境を実現します。

特長

01

他の機能との組み合わせが可能

断熱機能の他に各種光学特性や、遮音機能を組み合わせる事が出来ます。

02

デザイン性向上に寄与

高度な技術仕様にも対応しながら、デザイン性も高めます。

部位

ギャラリー

化学強化ガラス

化学強化ガラスとは

化学強化プロセスを経て、強度を高めたガラスです。

特長

01

軽量化に寄与

ガラスの厚みを薄くしても、化学強化によって強度を損なうことなく軽量化することができます。

部位

ギャラリー

曇りにくいガラス エグゼビュー®

曇りにくいガラスとは

高い耐久性能を確保した特殊な樹脂膜コートを施したガラスです。樹脂膜コート材が車内の水分を吸収し、ガラスの曇りを防止します。

特長

01

デフロスターの操作回数を低減

デフロスターの操作回数が低減し、ドライバーの利便性と実燃費の向上に貢献します。

02

安全性が向上

結露による光の散乱を防ぎ、ドライバーの視界確保による走行安全性を向上します。

部位

ギャラリー

併せてご覧下さい

透明導電膜付きウィンドシールド

赤外線カットガラス クールベール®

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

2024年12月

CES2025に出展

次世代モビリティ向け新製品を多数展示

次世代モビリティ向け新製品を多数展示

2024年9月

AGC の車載ディスプレイ用加飾カバーガラスが

車内インテリアにもたらす新たな世界観

車内インテリアにもたらす新たな世界観

併せてご覧下さい

車載ディスプレイ用カバーガラス

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

2024年1月

AGC CES2024 ダイジェスト

併せてご覧下さい

モビリティ

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

2024年1月

モビリティ社会をドライブするAGC

ジャパンモビリティショーで披露した最新技術と展望

ジャパンモビリティショーで披露した最新技術と展望

併せてご覧下さい

モビリティ

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

2023年12月

AGC、「CES2024」に出展

-世界初公開を含む次世代モビリティに対応した最先端ソリューションを展示-

-世界初公開を含む次世代モビリティに対応した最先端ソリューションを展示-

AGC(AGC株式会社、本社:東京、社長:平井良典)は、2024年1月9日から1月12日までラスベガスで開催される世界最大の技術展示会「CES2024」に出展します。「Detection(検知)」、「Connection(繋がり)」、「Comfortability(快適さ)」の3つの分野をテーマに、次世代モビリティの実現に向けて開発された20の最先端素材・ソリューションを展示する予定です。なお、CESへの出展は2023年に引き続き、2年連続となります。

AGCは110年以上にわたり、変化し続ける社会のニーズに対応し、革新的な素材とソリューションを提供してきました。今後、自動車のガラスが単なる窓ガラスから、マルチファンクション化するというビジョンのもとに、開発に取り組んでおり、その実現による経済的価値と社会的価値の両方の創出を目指しています。

【当社最高技術責任者(CTO) 倉田英之のコメント】

次世代モビリティ産業において、ガラスは一等地です。AGCグループは、創業以来、材料技術・機能設計・生産技術といったコア技術を磨き上げてきました。CES2024で紹介する先進的な素材・ソリューションにより、次世代モビリティにイノベーションを起こすことを目指しています。是非展示ブースにてご体感ください。

「Detection(検知)」

Wideye(ワイドアイ)

Wideyeは、LiDAR等の光を用いたリモートセンシングに用いられる波長領域に対応した、赤外線を透過する自動車用ガラスで、先進運転支援システムや自動運転システム用センサーのカバーに使用可能です。

「Connection(繋がり)」

5G通信対応ガラスアンテナ

車体のデザインを損なわないデザインのガラスアンテナは、5Gの全周波数に対応しています。既存の窓ガラスの室内側に設置することで、窓ガラスをアンテナに変えることができます。ラスベガスを拠点とするHalo.Car社では、5Gを利用した無人EVレンタカーサービスを展開しており、本ガラスアンテナを採用することで、5G通信の途絶低減を実現しています。

「Comfortability(快適さ)」

車載ディスプレイ用カバーガラス

当社は世界で初めて車載ディスプレイ用カバーガラスを販売開始しました。高度な加工技術・品質・強度、加えて反射防止膜や指紋付着防止膜などといった成膜技術の強みを活かして「安全設計」、「高い視認性」、「卓越したデザイン」を実現してきました。今回は大型曲面ディスプレイ用カバーガラスを展示する予定です。

詳しくは、AGCの展示ブース (#6667 LVCC West Hall Vehicle Tech & Advanced Mobility) にてご覧いただけます。

CES®について

CES®は、全米民生技術協会 (CTA) が主催する、世界最大のテクノロジー見本市です。詳細については、https://www.ces.tech/ をご覧ください。

| 展示品 | 用途 |

| FIRカメラ対応 フロントガラス | ADAS用FIR(遠赤外線)検知 |

| 360度センサー LIDAR用カバーガラス | 自動車用LiDARソリューション |

| 光学部品 / カバーガラス | LiDAR |

| 化学強化用特殊ガラス | スマホ、タブレット、PC等ディスプレイ用カバーガラス |

| 超撥水ガラス | モビリティ用途の窓ガラス、ルーフガラス、

センサー用カバーガラス |

| 5G通信対応ガラスアンテナ | 5G通信を搭載した自動車用ガラス |

| 建築物用5G技術 | 屋内カバレッジ改善ソリューション |

| 車載用3D ディスプレイカバーガラス | 自動車内装用ガラス |

| カラーシフトレスコーティング | 自動車内装情報表示 |

| 自動車用内装装飾ガラス | 自動車内装用ガラス |

| 自動車用ガラスの試作品オーダーメイド生産システム | 自動車用ガラス |

| 車載用吸音部材 | 自動車用の吸音機能部材 |

| 車窓ディスプレイ | エンターテインメント用途の自動車用窓ガラス |

| 調光サイドガラス | プライバシーをコントロールできる自動車用サイドガラス |

| Low-Eコート付調光パノラマルーフ | 調光可能な自動車用ルーフガラス |

| ヘッドアップディスプレイ用ガラス | ヘッドアップディスプレイ用ソリューション |

| フッ素樹脂電線被覆材 | EV向け電装関連部材 |

| 光電混載基板・光インターフェース部材 | 次世代高速通信に向けた半導体用部材 |

| 硫化物固体電解質 | 車載全固体電池 |

併せてご覧下さい

モビリティ

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

2023年11月

自動運転車の“眼”を高精度な状態に保つ

LiDARを保護しながら、パフォーマンスをサポートする

素材ソリューション

LiDARを保護しながら、パフォーマンスをサポートする

素材ソリューション

併せてご覧下さい

LiDAR用カバーガラス Wideye®

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

2023年11月

次世代モビリティ市場創出をけん引する素材⾰命

併せてご覧下さい

ビジョン

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

2023年10月

車載ディスプレイ用カバーガラス

「動く居住空間」となる 次世代自動車の価値を向上

「動く居住空間」となる 次世代自動車の価値を向上

併せてご覧下さい

車載ディスプレイ用カバーガラス

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

2023年9月

AGCの調光ガラス Digital Curtain®が

トヨタ自動車株式会社の「センチュリー」に採用

トヨタ自動車株式会社の「センチュリー」に採用

AGC(AGC株式会社、本社:東京、社長:平井良典)の調光ガラス Digital Curtain®*1が、2023年中にトヨタ自動車株式会社から発売される「センチュリー」に採用されました。透過光と視界を瞬時に制御できるDigital Curtain®を後部座席に使用することで、広く快適な車内空間の実現に貢献しています。なお、調光ガラスの車ドア部位への採用は、世界初*2となります。

トヨタ自動車株式会社から発売される新型「センチュリー」

今般採用されたDigital Curtain®は、調光モード(不透明な状態)では日差しの暑さ・眩しさを和らげるとともにプライバシーを確保し、透過モード(クリアな状態)では開放感を楽しむことのできる調光ガラスです。これまで調光ガラスはパノラマルーフなど開閉しない部位に採用されていました。今回のDigital Curtain®は、長期間の風雨や太陽光に耐えられる化学耐久性に加え、開閉や昇降などの機械的耐久性も実現しました。さらに窓ガラス周辺の黒セラミックデザインを可能な限り細くすっきりと造ることで、「センチュリー」の格調高い意匠性に相応しいドアデザインとして評価され、世界初となる調光ガラスの後部ドア部位への採用に至りました。

Digital Curtain®の採用により、シェードは不要となり、より広く、先進的で快適な後部座席空間が実現するとともに、プライバシー性も向上します。

自動車用ガラスに求められる機能が高度化・多様化する中、AGCグループは最適な素材・ソリューションの提供を通じ、新たなモビリティ社会の実現に貢献していきます。

*1 当社の自動車向けの調光ガラス商品群のグループブランド。

*2 当社調べ。ドア部位に合わせガラス仕様の調光ガラスが採用されることは世界初。

調光モード(スイッチオフの不透明な状態)

透過モード(スイッチオンのクリアな状態)

併せてご覧下さい

調光ガラス Digital Curtain®

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

2023年7月

高性能と意匠性を兼ね備える

AGCの5G通信対応ガラスアンテナ

AGCの5G通信対応ガラスアンテナ

併せてご覧下さい

アンテナ

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

2023年6月

FIRカメラ対応フロントガラスで

夜間の歩行者交通事故ゼロに

挑戦するAGC

夜間の歩行者交通事故ゼロに

挑戦するAGC

併せてご覧下さい

センサー

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

2023年1月

次世代モビリティの未来を指し示す

LEXUS×AGCの挑戦

LEXUS×AGCの挑戦

併せてご覧下さい

調光ガラス Digital Curtain®

製品に関するお問い合わせ

下のお問い合わせフォームより承ります。必要事項を入力の上、送信ください。

2022年12月

AGC、「CES2023」で次世代モビリティを実現する製品・技術を展示

AGC株式会社(以下AGC、本社:東京、社長:平井良典)は、2023 年 1 月 3 日から 8 日までラスベガ スで開催される世界有数の技術展示会「CES2023」に出展します。3 日、4 日はメディア向け、5 日から一般向けに 公開されます。当社は、新製品を含む 17 製品を展示する予定です。

AGCは、110 年以上にわたり、建築用・自動車用・ディスプレイ用ガラスのリーディングカンパニーとして、高品質な 製品をグローバルに供給してきました。現在では、ガラス、電子、化学品、セラミックスの各分野で培った技術力を活かし、 自動運転をはじめとするモビリティサービスの需要拡大に対応したさまざまな最先端素材やサービスを提供しています。

今回のCESでは、一般的な自動車用ガラスでは透過しない遠赤外線を透過する特殊ガラスを使用した「FIR(遠 赤外線)カメラ対応フロントガラス」を展示予定です。フロントガラスの室内側に取り付けられた通常の可視カメラとFIR カメラのセンサーを融合させることで、夜間や悪天候時の歩行者・自転車事故のリスクを低減することが可能となります。

また、自動運転に必要なカメラやLiDAR部品を搭載するために必要な強度や光学性能を持った、AGCのガラス組 成・加工技術も展示します。その他、5G-sub6 ガラスアンテナ、車載用 3D曲面カバーガラスなど、様々なソリューション を展示予定です

https://www.agc.com/news/pdf/20221208.pdf

CEO平井のコメント 「CESは世界で最も影響力のある技術展示会の一つであり、AGCの力を世界にアピールする絶好の舞台です。当社の 次世代モビリティ関連製品・ソリューションが、CESの来場者の間で話題を呼ぶことを期待しています。AGCが提供す る素材は、間近で見て、体験していただくことで伝わる魅力があります。一人でも多くの方に、私たちの提供する価値を 肌で感じていただき、製品を採用していただければ幸いです。」

ブース情報 LVCC - West Hall Vehicle Tech & Advanced Mobility #4377 上記に加え、Wideye "ソリューションの専用ブース(#6557)と "FeelInGlass "製品の専用ブース(#6674)を 設けています。

2022年5月

AGCのLow-Eコート付き調光パノラマルーフが トヨタ自動車株式会社 LEXUS初のBEV専用モデル「RZ」に採用

従来のパノラマルーフは、光を取り込み開放的な車内空間を実現する一方、日射熱や外気の影響を受けやすいことから、車内を快適に保つためにサンシェードを必要とし、暑さ寒さの問題から開放感を満喫できない課題がありました。

今般当社が開発した車載用特殊Low-Eコート技術は、高い品質と先進性を追求するLEXUSブランドに要求される信頼性評価をクリアし、今までにない遮熱・断熱性能を実現することで、課題だった夏の暑さ・冬の寒さを大きく抑制しました。またシェードレス設定を可能にすることにより、車体の軽量化やヘッドクリアランス(座席に座った際の頭頂部から天井までの距離)の確保にも寄与しています。

さらに、瞬時に透過光を制御し車内の光環境を調整可能な調光タイプもご用意し、新時代のLEXUSに新しい楽しさ、快適さ、体験価値を提供します。

AGCグループは、中期経営計画 AGC plus-2023 のもと、モビリティ事業を戦略事業と位置付けています。CASEの進展に伴い、自動車用ガラスに求められる機能が多様化する中、最適な素材・ソリューションの提供を通じ、新たなモビリティとサステナブルな社会の実現に貢献していきます。

*1 BEV:Battery Electric Vehicle(電気自動車)の略称

*2 Low-Eガラス:Low emissivity (低放射) ガラスの略称。特殊な金属膜をコートすることで放射による伝熱が抑えられ、遮熱・断熱性能が高いガラス

<調光ガラスWONDERLITE® Dx>

2枚のガラスの間に挟み込んだフィルム中の特殊材料の分散⇔配向を電圧でコントロールすることで、調光モード⇔透過モードを瞬時に切り替えられます。

2022年4月

AGC、国際ガラス年 2022 特別企画展「ガラスの正体」を開催

本企画展では、当社がこれまで⽣み出してきた機能価値として、既存のガラス製品や、スマートミラーを⽤いた新しい

ユーザーインターフェース、電波や紫外線を可視化するVR技術などをわかりやすく体験いただけます。更にライフサイエンス

や環境・エネルギー分野に貢献するガラス製品や、環境対応型ガラス製造プロセス技術などの映像展⽰を通して、持続

可能な社会に貢献する製品・技術も紹介します。

ユーザーインターフェース、電波や紫外線を可視化するVR技術などをわかりやすく体験いただけます。更にライフサイエンス

や環境・エネルギー分野に貢献するガラス製品や、環境対応型ガラス製造プロセス技術などの映像展⽰を通して、持続

可能な社会に貢献する製品・技術も紹介します。

加えて、世界各地の砂や原料を⽤いて「⼟地の記憶」を封⼊したガラス作品の紹介や、AGCが新たに開発した分相

ガラス*1 を⽤いたアート作品などを通して、ガラスの持つ情緒的価値を再発⾒いただき、来場いただいた⽅々に「ガラスの

正体」とは何か思いをめぐらせていただきます。そこで得られた発⾒や気付きを、来場されたお客様同⼠やAGC社員と

共有することで、ガラス産業の未来の発展に向けた新たな発⾒や繋がりが⽣まれる空間を⽬指します。

ガラス*1 を⽤いたアート作品などを通して、ガラスの持つ情緒的価値を再発⾒いただき、来場いただいた⽅々に「ガラスの

正体」とは何か思いをめぐらせていただきます。そこで得られた発⾒や気付きを、来場されたお客様同⼠やAGC社員と

共有することで、ガラス産業の未来の発展に向けた新たな発⾒や繋がりが⽣まれる空間を⽬指します。

AGCはガラスのリーディングカンパニーとして「国際ガラス年 2022」にダイヤモンドスポンサーとして協賛しています。本

特別企画展のみならず、様々なイベントを主催することで、ガラスの魅⼒を世界中に発信していきます。

特別企画展のみならず、様々なイベントを主催することで、ガラスの魅⼒を世界中に発信していきます。

*1︓AGC特有の素材制御技術によりガラスの中に屈折率の異なるナノオーダーの粒⼦を均⼀に分散させることで作られたガラス。

この特殊な技術加⼯により、太陽光に⾒⽴てた⽩⾊光を当てたとき、光の波⻑よりも⼩さい粒⼦によって短波⻑の光(主に⻘⾊)が

選択的に散乱されます。この現象が⾃然界でいう⾚い⼣陽や⻘空を作り出し⼈の⼼を癒します。

この特殊な技術加⼯により、太陽光に⾒⽴てた⽩⾊光を当てたとき、光の波⻑よりも⼩さい粒⼦によって短波⻑の光(主に⻘⾊)が

選択的に散乱されます。この現象が⾃然界でいう⾚い⼣陽や⻘空を作り出し⼈の⼼を癒します。

<ご参考>

■開催概要

名称︓ 国際ガラス年特別企画展「ガラスの正体」

期間︓ 2022 年 4 ⽉ 4 ⽇(⽉)〜2022 年 9 ⽉ 2 ⽇(⾦) (⼟⽇祝休)

会場︓ AGC 横浜テクニカルセンター 横浜市鶴⾒区末広町 1-1

ディレクション︓ 株式会社アートフリーク

URL︓ https://www.agc.com/identity-of-glass/

お問い合わせ︓ agc_ml.IYoG2022@agc.com

2022年3月

AGC、本田技研工業より優良感謝賞 「サステナビリティ部門」 を受賞

優良感謝賞 「サステナビリティ部門」 は、ESG 領域において優れた取り組みを行った取引先に贈呈される賞です。

AGCグループは、継続的な社会的・経済的価値の向上を目指し、サステナビリティ経営の推進に取り組んでいます。

今回の受賞は、すべての事業部門におけるサステナビリティ目標の設定やその実現に向けた実行力あるサステナビリティ委員会の設置、インターナルカーボンプライシングの導入など、当社のこれまでの活動および中長期的な戦略が評価されたものです。

AGC グループは、今後も社会やお客様の目指す 「2050 年全製品・企業活動を通じたカーボンニュートラル」 に向けた多様なニーズに応えられるよう、循環型社会への発展に貢献していきます。

2022年1月

AGC、「国際ガラス年2022」に協賛

国連は、特定分野の活動について国際社会への貢献を周知・促進するため、1959年より毎年「国際年」を宣言しています。2022年は、灯台などに使われているフレネルレンズの発明から200年、ツタンカーメンの墓からエジプトガラスが発見されて100年になります。この記念すべき年を、人類文明の発展と共に歩んできたガラスという素材を称える年とすべく、世界各国から1,600件を超える賛同書が寄せられました。その結果、2021年5月の国連総会において、「国際ガラス年2022」の決議案が採択されました。なお人工的に作られた物質として、ガラスは初めての「国際年」採択となります

「国際ガラス年2022」の目的は下記の通りです。

° ガラス材料およびガラス産業の過去、現在、未来を称え祝福すること

ガラスの化学と芸術と文化に関わる世界の様々なイベントに取り組むこと

産学のガラス研究、ガラスに関わる博物館や美術館の取り組みにより、世界中のあらゆる地域における持続性のある発展に貢献すること

次世代を担う若手のためのガラスの科学と工学、ジェンダーの平等、発展途上国の要求に対する取り組みを支援する国際協調の枠組みを作ること

AGCはガラスのリーディングカンパニーとして、「国際ガラス年2022」のスポンサーシップのみならず、様々なイベントを主催することで、ガラスの魅力を世界中に発信していきます。

以 上

以 上

<ご参考>

■「国際ガラス年2022」の国際組織

「国際ガラス年2022」は、18の地域組織(RO: Regional Organization )から構成されています。

国際委員会URL:https://iyog2022.org/

日本委員会URL:https://iyog2022.jp/

■「国際ガラス年2022」の主なイベント

日本オンラインオープニングセレモニー 1月28日(日本)

国際開会式 2月10日~11日(スイス)

合衆国国家ガラスデー 4月5日~7日(米国)

国際高度技術産業会議 4月11日~15日(中国)

国際ガラス年2022「画像と動画コンテスト」 6月1日~8月31日(予定)(日本)

国際ガラス会議 7月3日~8日(ドイツ)

ベネチアガラス週間 9月4日~12日(イタリア)

国際閉会式 12月8日~9日(日本)

2021年9月

AGC 横浜テクニカルセンターのオープニングセレモニーを開催 - 社内外をシームレスにつなぐ新研究開発体制スタート -

社会の変化のスピードがますます速くなり、素材開発にもスピードの加速が求められています。このような中で「社内外にシームレス&融合・反応・協創の場」をコンセプトに、2018 年 4 月より新研究棟の建設に着手、2020 年 11 月には社内外の協創を加速させる場として協創空間「AO(アオ/AGC OPEN SQUARE)」をオープンしました。そして2021 年 6 月に分散していた研究開発組織の移設・統合を完了させ、本日より新研究開発体制をスタートします。

AGC 横浜テクニカルセンター外観

社会の変化のスピードがますます速くなり、素材開発にもスピードの加速が求められています。このような中で「社内外にシームレス&融合・反応・協創の場」をコンセプトに、2018 年 4 月より新研究棟の建設に着手、2020 年 11 月には社内外の協創を加速させる場として協創空間「AO(アオ/AGC OPEN SQUARE)」をオープンしました。そして2021 年 6 月に分散していた研究開発組織の移設・統合を完了させ、本日より新研究開発体制をスタートします。

AGCグループCEOの平井は、開会挨拶において「開港以来、常に新たな文化を積極的に受け入れ発展し続けるこの地にちなんで「横浜」の地名をいただき、AGC横浜テクニカルセンターとしました。開発拠点の進出も相次ぐ「横浜」で社内外の技術を融合しながら最先端技術の開発に取り組み、日本のものづくりの更なる発展に貢献していきます。」と述べています。

AGC グループは、経営方針 AGC plus 2.0 のもと社内外の協創を通じ、お客様に満足いただける、新たな価値をプラスした製品やソリューションを提供できるよう、技術革新を進めていきます。

2021年3月

AGCのガラス製透明スクリーン Glascene®が車窓モビリティサイネージサービスに採用

AGCのガラス製透明スクリーン Glascene®が車窓モビリティサイネージサービスに採用

AGC(AGC株式会社、本社︓東京、社長︓平井良典)のガラス製透明スクリーンGlascene®(グラシーン)が、株式会社ニューステクノロジーとS.RIDE株式会社が本年 6 月より開始予定のタクシー車窓モビリティサイネージサービス「THE TOKYO MOBILITY GALLERY Canvas」に採用されました。本製品は、プロジェクターの映像を投影できるガラス製透明スクリーンです。映像を投影していない時は透明な窓ガラスですが、投影時はクリアな映像を映し出すことができます。

AGCのガラス製透明スクリーンGlascene®は、特殊なスクリーンフィルムを、2 枚のガラスで挟み込んだ合わせガラス構造です。これまで主に商業施設や店舗、ショールームの窓ガラスとして映像演出用途に採用されています。

今回採用される「THE TOKYO MOBILITY GALLERY Canvas」では、タクシーの空車時間を活用し、サイドガラスに広告を投影することで、自動車用窓ガラスが新たな情報発信源として活躍します。自動車用窓ガラスとして求められる安全性・耐久性を確保しながら、高コントラストな広告を投影することが可能です。

AGCグループは、経営方針AGC plus 2.0 の下、お客様に「新たな価値・機能」を、プラスする製品づくりに取り組んでいます。今後もお客様に満足頂ける、新たな価値をプラスした製品をご提供できるよう技術革新を進めていきます。

2021年1月

AGCの大型・曲面車載ディスプレイ用カバーガラスが キャデラックの新型「エスカレード」に採用

キャデラックの新型「エスカレード」の革新的なデザインのディスプレイは 3 つの画面から構成され、それぞれメータークラスター情報 やナビゲーション、インフォテイメントなど、ドライバーに必要な多種多様な情報を表示します。また、高度な曲面成形技術を用いた AGCの大型・曲面車載カバーガラスを大小 2 枚使用することで 38 インチ相当のディスプレイとして一体化され、上質且つ先進 的なインテリアデザインの実現に寄与しています。

AGCの車載ディスプレイ用カバーガラスは、独自の設計・評価プロセスにより、自動車用内装材として求められる安全性を確保 しており、AGCが開発した特殊な製法で曲げることでP-OLEDディスプレイおよびガラス本体にかかる応力負荷を低減し、長期 的な強度と形状安定性を実現しています。また、AGCが多数の特許を保持するコーティングや装飾印刷の技術によって、高い 視認性とスムーズなタッチパネル操作に求められる機能(防汚処理、耐摩耗性)を有しています。

AGC グループは、経営方針 AGC plus の下、世の中に「安心・安全・快適」を、お客様に「新たな価値・機能」を、プラスする 製品づくりに取り組んでいます。今後も業界トップシェアを誇る車載ディスプレイ用カバーガラスのリーディングカンパニーとして、お客 様に満足頂ける、新たな価値をプラスした製品をご提供できるよう技術革新を進めていきます。

2020年6月

AGCの調光ガラスWONDERLITE®Dxが トヨタ自動車株式会社新型ハリアーに世界初採用

当社の調光ガラスWONDERLITE®Dxは、2枚のガラスの間に特殊なフィルムを挟み込む合わせガラスの構造になっており、調光モード(不透明な状態)では日差しの眩しさを和らげ、透過モード(クリアな状態)では開放感を楽しめ、365日いつでもパノラマルーフから心地よい光が降り注ぐ車内空間を実現します。

調光モード(スイッチオフの不透明な状態)

AGCグループは、経営方針AGC plusの下、世の中に「安心・安全・快適」を、お客様に「新たな価値・機能」をプラスする製品づくりに取り組んでいます。今後もお客様に満足頂ける、新たな価値をプラスした製品をご提供できるよう技術革新を進めてまいります。

透過モード(スイッチオンのクリアな状態)

1当社調べ。

2写真は、新型ハリアーのパノラマルーフとは異なる。

◎本件に関するお問い合わせ先: AGC株式会社 広報・IR 部長 玉城 和美 (担当:宮川 TEL: 03-3218-5603 E-mail: info-pr@agc.com) *個人情報は当社プライバシーポリシーに従ってお取扱いをさせていただきます。

2019年9月

AGCの車載ディスプレイ用カバーガラスがLEXUSの新型「RX」に採用

LEXUSの新型「RX」は、ラグジュアリーSUVとしての上質さと先進性が融合したインテリアが特徴です。12.3インチおよび8インチ(海外仕様、日本国内仕様は12.3インチのみ)のナビゲーションディスプレイに採用されたAGCの車載カバーガラスは、ガラス自体のもつ質感によって上質なインテリアにマッチするだけでなく、高い視認性や、ディスプレイのタッチパネル化に求められる機能(防汚処理、耐摩耗性)を有しています。

AGCは、2013年に世界で初めて、車載ディスプレイ用カバーガラスを素板から加工まで一貫生産する体制を整え販売を開始しました。2017年からは、平面形状に加えて曲面形状も生産・販売を開始しています。 車内のディスプレイのサイズが大型化、形状が複雑化する中で、AGCの車載カバーガラスは独自の設計・評価プロセスにより自動車用内装材として求められる安全性を確保しつつ、多数の特許を保有するコーティングや装飾印刷の技術によって、ディスプレイの視認性や操作性の向上にも寄与しています。

AGCグループは、経営方針AGC plus の下、世の中に「安心・安全・快適」を、お客様に「新たな価値・機能」を、プラスする製品づくりに取り組んでいます。今後も車載ディスプレイ用カバーガラスのパイオニアとして、お客様に満足頂ける、新たな価値をプラスした製品をご提供できるよう技術革新を進めてまいります。

◎本件に関するお問い合わせ先:

AGC株式会社 広報・IR部長 玉城 和美

担当:太田

TEL: 03-3218-5603

E-mail: info-pr@agc.com

2019年5月

世界初、28GHz帯に対応する5G端末向けのガラスアンテナで通信に成功

28GHz帯の周波数は、これまで第4世代移動通信方式(以下、LTE)などで利用していた周波数帯よりも直進性が強く、車室や建物内で通信するときには電波が弱まってしまう傾向があります。そこで電波が弱まる前に、車室や建物のガラス面に貼り付けられた本アンテナで電波を送受信することで、安定した5G高速通信が可能になります。

また、本アンテナは透明性が高く、建物や車両などに設置しても視野をさえぎらず、また景観を損なうことがないため、車両や建物などへの設置の可能性が広がります。

また、本アンテナは透明性が高く、建物や車両などに設置しても視野をさえぎらず、また景観を損なうことがないため、車両や建物などへの設置の可能性が広がります。

時速約30kmで走行中の実験用車両の窓ガラスに本アンテナを貼り付け、車内での5G通信速度を検証する実証実験を2019年4月22日(月)~2019年5月28日(火)に、東京都墨田区周辺の市街地において行いました。時速約30kmで走行中の実験用車両の窓ガラスに本アンテナを貼り付け、車内での5G通信速度を検証した結果400MHzの帯域幅で下り最大3.8Gbps、基地局から半径約100mのエリアにおいて平均1.3Gbpsの5G通信に世界で初めて※1成功しました。

今後もドコモ、AGCおよびエリクソンは、本アンテナを複数束ねてデータの送受信を行うMassive MIMO対応によるさらなる通信速度の向上だけでなく、基地局の設置が困難な場所や一時的な5Gの需要があるような環境において、本アンテナの活用による5Gのエリア拡充や用途の拡大などの取り組みを進めます。

【実証実験動画】

URL : https://youtu.be/j0RY-o8rYXs

2019年3月

AGC、自動車用ガラスアンテナの開発体制をグローバル3 極で構築

来たるモビリティ社会には、カメラやLiDAR、センサーなどの機器によるクルマ同士あるいはクルマとすべてのものがつながるV2X を実現する通信機能が求められます。そうした中、受発信アンテナの搭載および電波の出入り口として、自動車用ガラスの役割が増しています。

また、クルマのデザインを損ねることなく、各種放送波の受信や5G などの高速通信に最適なガラスアンテナデザインを設計するためには、開発段階から高度なシミュレーション技術の応用や高精度な計測技術が求められます。

AGCは、40 年以上にわたり自動車用ガラスアンテナの研究・開発・製造において業界をリードしてきました。既に、日本と米国の電波暗室で自動車用ガラスアンテナの設計を実施し、お客様に最適な自動車用ガラスアンテナを提供しています。欧州での電波暗室竣工により、お客様の開発活動をグローバルに支援し、かつIoT 時代の“つながる”クルマに対応するアンテナ開発を加速していく体制が整いました。

AGCグループは、経営方針AGC plus の下、モビリティ分野を戦略事業のひとつに位置付けています。日米欧3極に電波暗室を持つ強みを活かし、 “つながる”クルマの実現に貢献します。

※AGC調べ(2019 年3 月18 日現在)

◎本件に関するお問い合わせ先:

AGC株式会社 広報・IR 部長 玉城 和美

(担当:森永 TEL: 03-3218-5603

E-mail: info-pr@agc.com)

Reference

About anechoic chambers

Anechoic chambers are facilities that completely cut off external electromagnetic waves to measure and evaluate an electronic device’s reception of electromagnetic waves. Inside the anechoic chamber, the electromagnetic waves emitted from a “Connected” device are measured.

AGC's development framework for automotive on-glass antennas

画像:今回竣工した欧州の電波暗室

動画:https://youtu.be/KH46Nt-3hvw

2017年10月

AGC旭硝子の切子調ガラスオーナメントが トヨタ自動車株式会社LEXUSの新型「LS」に採用

LEXUSの新型「LS」は、LEXUSの象徴としてブランドの変革を体現するフラッグシップモデルで、「TAKUMI CRAFTSMANSHIP」をテーマに、日本の匠の技を見どころとした繊細で個性的なインテリアが特徴です。ドアトリム部分に採用された当社の切子調ガラスオーナメントは、日本の伝統技術と最新の生産技術が融合した独創的な空間演出に貢献しています。

当社は本製品の製造にあたり、ガラス工芸家の原版意匠を再現するため「工芸品を工業製品に」をテーマに掲げ日本各地の高い生産技術を結集しました。当社の金型設計技術とガラス成形技術に加え、日本各地の精密加工・特殊研磨工程を取り入れた量産プロセスを確立し、世界初※1のドアトリムオーナメントを作り上げました。

AGCグループは、経営方針AGC plusの下、世の中に「安心・安全・快適」を、お客様に「新たな価値・機能」をプラスする製品づくりに取り組んでいます。今後もお客様に満足頂ける、新たな価値をプラスした製品をご提供できるよう技術革新を進めてまいります。

※1 2017年10月現在、当社調べ。

本件に関するお問合せ先

AGC旭硝子 経営企画部 広報・IR室長 玉城 和美

担当:駒崎

TEL: 03-3218-5603

E-mail: info-pr@agc.com

2017年9月

AGC旭硝子の曲面形状の車載ディスプレイ用カバーガラスを搭載した世界初の量産車が登場

新型 Audi A8のコックピットには上下に2つのタッチスクリーン式ディスプレイがあり、安全で快適な運転に必要な情報を表示し、コントロールできるようになっています。上部のなめらかな曲線を描く10.1インチの大型ディスプレイでは、ナビゲーションやインフォテインメントシステムを表示し、下部のディスプレイでは、システムを操作する仕様です。上部のディスプレイにはAGCの曲面カバーガラスが、下部のディスプレイには平面カバーガラスが採用されています。

なめらかな形状と周囲に溶け込む色調により、一体感あるダッシュボードデザインの実現に寄与している点AGC独自の三次元曲面加工技術と、色調を工夫した加飾印刷が貢献しています素板から加工まで一貫生産し、高い品質をご提供できる点化学強化ガラスの製造、成形、映り込みを抑え指紋をつきにくくする等の光学成膜、加飾印刷まですべての工程をAGCグループで生産しています

AGCグループは、経営方針AGC plusの下、世の中に「安心・安全・快適」を、お客様に「新たな価値・機能」を、プラスする製品づくりに取り組んでいます。今後も車載ディスプレイ用カバーガラスのパイオニアとして、お客様に満足頂ける、新たな価値をプラスした製品をご提供できるよう技術革新を進めてまいります。

※2017年9月14日時点、AGC旭硝子調べ

本件に関するお問い合わせ先

AGC旭硝子 経営企画部 広報・IR室長 玉城和美

担当:高橋

TEL: 03-3218-5603

E-mail: info-pr@agc.com

2017年6月

鉄道用ガラスが新たな寝台列車「TWILIGHT EXPRESS 瑞風(みずかぜ)」に採用

「美しい日本をホテルが走る。~上質さの中に懐かしさを~」をコンセプトにした「瑞風」には、車窓から山陰・山陽地域の豊かな歴史・文化や美しい自然を楽しんで頂くための様々な仕掛けが組み込まれています。この「瑞風」の客室・運転室の窓に当社の鉄道用安全ガラスが採用されました。

客室の窓には、夏の暑さ・冬の寒さからお客様を守るだけでなく、紫外線も99%カットするLow-Eペアガラスが採用され、美しい車窓と快適性を共に実現しています。また、展望デッキの側面から天井まで広がる大型窓にも曲面形状のLow-Eペアガラスが使われ、日中の車窓だけでなく夜の星空も快適に楽しんで頂けます。

AGCグループは、新幹線を始めとする鉄道の安全ガラスを50年以上にわたり手掛けて参りました。今後もAGCグループが持つ素材・技術の多様性を活かしながら、経営方針AGC plusで掲げる「安心・安全・快適」に繋がる更なる製品を開発・提供し続けていきます。

本件に関するお問い合わせ先

2017年5月

AGC旭硝子、世界で初めて三次元曲面形状の車載ディスプレイ用カバーガラスを量産開始

AGCグループの車載ディスプレイ用カバーガラスは、車内の高級感やデザイン性を高め、反射を抑える等の表面処理により視認性・操作性を向上させる素材として、カーナビゲーションシステムや 運転情報表示パネルで採用が進んでいます。2013年よりグループ会社であるAGCディスプレイグラス米沢(山形県米沢市、社長:三谷孝)で車載用専用ラインによる平面形状タイプの生産を開始し、旺盛な需要に対応するため2016年4月には生産能力を増強しました

今般量産開始した車載ディスプレイ用カバーガラスは、AGCグループ独自の技術による三次元曲面形状のガラスに化学強化・光学成膜・印刷等の表面処理も施したもので、自動車の内装デザイン向上に寄与します。また、今後も車載ディスプレイの大型化や曲面化が進むことが見込まれるため、京浜工場において曲面形状の車載ディスプレイ用カバーガラスの生産能力を増強します。AGCグループは、多様化するニーズや拡大する需要に対しいち早く供給体制を整え、車載ディスプレイ用カバーガラスのリーディングカンパニーとしての地位を確固たるものにしていきます。

AGCグループは、経営方針 AGC plus の下、世の中に「安心・安全・快適」を、お客様に「新たな価値・機能」を、プラスする製品づくりに取り組んでいます。今後も車載ディスプレイ用カバーガラスのパイオニアとして、お客様に満足頂ける、新たな価値をプラスした製品をご提供できるよう技術革新を進めてまいります。

(注1)2017年5月23日時点、AGC旭硝子調べ

2017年5月

AGC旭硝子の「WONDERLITE®」がクルーズトレイン「TRAIN SUITE 四季島」に採用

四季島は、「時間と空間の移り変わりを楽しむ列車」をテーマにしたJR東日本の豪華クルーズトレインです。四季島は、車両ごとに異なるコンセプトを扱っており窓や内装で様々な種類のガラスが使われています。中でも先頭車両の展望エリアは日本の四季おりおりの眺望を楽しんでもらうことをコンセプトにしており、日中快適に景色をご覧いただくためスイッチ操作によって太陽光の調節機能を持つ調光ガラス「WONDERLITE®」を採用頂きました。また、他の客室や運転室にも当社の鉄道用安全ガラス・インテリア用ガラスが用いられています。

「WONDERLITE®」は太陽光透過率の調節が可能な車両向け調光ガラスです。特殊コーティング(注1)を施しているため透明モード時でも日焼けの原因となる紫外線や暑さの原因となる赤外線をカットします。調光機能(注2)と特殊コーティングの効果的な組み合わせは、乗客に理想的な乗車環境を提供し、エアコン負荷など消費電力削減にも大きく貢献します。

AGCグループは、新幹線を始めとする鉄道の安全ガラスを手掛けて50年を超える経験があります。今後もAGCグループが持つ素材・技術の多様性を活かしながら、経営方針AGC plusで掲げる「安心・安全・快適」に繋がる更なる製品を開発・提供し続けていきます。

注1:太陽光線エネルギー制御による遮熱性を大きく向上させるガラス表面の金属薄膜コーティング

注2:合わせガラス内部の微粒子を電圧により整列させてガラスを透明にする調光素子技術

2016年8月

AGC旭硝⼦、北アフリカへ初進出

モロッコは近年欧州向け⽣産拠点として位置づけられていることなどを背景として、北アフリカで最も⾼い経済成⻑が続いており、すでに欧州⾃動⾞メーカーが同国への進出を決定または予定しております。 また、欧州の⾃動⾞⽣産台数は毎年2千万台を超え、今後も2%前後の成⻑が続くものと⾒込まれます。このような事業環境を踏まえてAGCグループは、モロッコ北部沿岸部・ケニトラ州にINDUVER社と合弁で⾃動⾞⽤ガラス事業会社を設⽴することに致しました。2019年に商業⽣産を開始し、合せガラス、強化ガラスなど(⽣産能⼒:年間110万台相当)の⾼付加価値の製品・サービスを欧州、北アフリカのお客様に提供する予定です。

AGCグループは経営⽅針 AGC plus の下、⾃動⾞⽤ガラス事業を成⻑事業の⼀つと位置づけ、拠点展開を拡充してきました。今回の北アフリカ進出により、欧州および北アフリカの⾃動⾞⽤ガラス需要に応え、更なる企業価値向上を図っていきます。

<ご参考>

INDUVER社について

代表 Hakim Abdelmoumen

所在地 カサブランカ市(モロッコ)

設⽴ 1947 年

従業員数 368 名(2014 年12 ⽉末時点)

事業内容 主に⾃動⾞⽤、建築⽤、産業⽤ガラスの製造

販売

AGCオートモーティブ・ヨーロッパ社について

当社の連結⼦会社AGCガラス・ヨーロッパ社(AGC旭硝⼦100%出資、ベルギー)の100%出資⼦会社であり、⾃動⾞⽤ガラス事業部⾨。

2016年3月

AGC 旭硝子、車載ディスプレイ用カバーガラスの供給体制を拡充 ―業界のパイオニアとして、旺盛な需要に対応―

AGCグループでは、化学強化用特殊ガラスDragontrail®に、化学強化処理、光学薄膜コーティング、装飾印刷等 の加工を施した車載ディスプレイ用カバーガラスを販売しており、2013 年からADY社の専用ラインで同製品を生産して います。今後も更なる需要拡大が見込まれることから、これに対応する生産能力の増強を進めており、本年 4 月からそ の稼働を開始します。

AGCグループは、化学強化ガラスを用いた、車載用に適したディスプレイ用カバーガラスの提案を進めてまいりました。 クリアで硬い光沢感のあるガラスは、建築やインテリアに先進性や高級感などデザイン性を高める素材として広く用いられ ています。更に近年スマートフォンやタブレット型端末が急速に普及した事により、ガラスはいっそう私たちの生活に身近な 存在となっています。 AGCグループの車載ディスプレイ用カバーガラスは、コーティングや装飾印刷によって、車載用ナビゲ ーションシステムや運転情報表示パネルの視認性や操作性を向上させており、既に 30 車種以上に採用が決定してい ます。AGCグループは、車載ディスプレイ用カバーガラスのリーディングカンパニーとして、供給体制を拡充し、更なる需要 拡大に対応していきます。また、よりデザイン性の高い、三次元曲面形状の車載ディスプレイ用カバーガラスについても、 量産に向けた準備を進めています。

AGCグループは、経営方針 AGC plus の下、世の中に「安心・安全・快適」を、お客様に「新たな 価値・機能」を、プラスする製品づくりに取り組んでいます。今後も車載ディスプレイ用カバーガラスのパイオ ニアとして、お客様に満足頂ける、新たな価値をプラスした製品をご提供できるよう技術革新を進めてまいります。

AGC 旭硝子 経営企画部 広報・IR 室⻑ 小林 純一

(担当:烏山 TEL: 03-3218-5603 E-mail:info-pr@agc.com)

2016年3月

AGC旭硝⼦がブラジル第2 フロート⼯場を新設 - ガラス⽣産能⼒を 2.4 倍に増強

AGC旭硝⼦は、新興国市場での事業拡⼤を成⻑戦略の⼀つに掲げ、2011 年にAGCガラス・ブラジル社を設⽴し ました。2013 年以降順次、建築⽤および⾃動⾞⽤ガラス素板、ミラーおよび建築⽤各種コーティング加⼯製品、⾃動 ⾞⽤合わせガラスおよび強化ガラスを出荷し、その品揃え、品質およびサービスが市場で認知され同社事業は着実に拡 ⼤しています

ブラジルは約2億⼈の⼈⼝を抱え、若年層⽐率が⾼いことや、豊富な天然資源等を背景として、中⻑期的な観点 では経済成⻑が続くものと予想されます。建築⽤・⾃動⾞⽤ガラスにおいても、需要成⻑が⾒込まれるため、現状年間 22 万トンの⽣産能⼒に新たに年間31 万トンを加え、年間53 万トンに増強します

AGCグループは、今後も新興国において拡⼤する需要を着実に取り込み、経営⽅針AGC plus のもと売上⾼の 拡⼤を⽬指します。

【AGCガラス・ブラジル社の概要】

社⻑ ダビデ・カペリーノ

本社所在地 サンパウロ州 グアラティンゲタ市

出資⽐率 AGCグループ 100%

事業内容 建築⽤ガラス・⾃動⾞⽤ガラスの製造・販売

従業員数 525 名(2015 年12 ⽉末時点)

2016年3月

AGC旭硝子、中国蘇州市の生産子会社の社名を変更 ―中国・自動車用ガラス事業の三拠点一体運営を加速

同生産子会社では自動車用ガラス素板、太陽電池用カバーガラスを生産していましたが、2014年には太陽電池用カバーガラスの生産を停止する一方で、自動車用加工工程を新たに設置し、2015年には自動車用ガラスの一貫生産体制を整えました。今般社名を変更し、自動車用ガラス生産拠点であることを明らかにするとともに、同事業を行う秦皇島、仏山拠点との一体運営を加速していきます。

<社名変更内容>

新社名 旭硝子汽車玻璃 (蘇州) 有限公司 AGC Automotive(Suzhou) Co. Ltd.

旧社名 旭硝子特殊玻璃 (蘇州) 有限公司 AGC Flat Glass(Suzhou) Co .Ltd.

中国における自動車生産台数は、2016年には2,600万台に到達する見込みであり、今後も引き続き高い成長が予想されます。これに伴い、自動車用ガラスの需要も確実に増加することが見込まれます。当社は1995年に河北省秦皇島の自動車用ガラス会社へ資本参加して以来、2006年には広東省仏山市に新社を設立、自動車用ガラス事業の強化、充実を図ってきましたが、今後の需要増に対応するため、2015年より生産能力のさらなる拡大と体制構築を実施しています。

AGCグループは、自動車用ガラス事業において、資産効率を高めながら、拡大する中国での需要を着実に取り込み、経営方針 AGC plus で掲げる企業価値の向上を目指していきます。

旭硝子特殊玻璃(蘇州)有限公司の沿革

2004年 旭硝子浮法玻璃(蘇州)有限公司設立

2005年 旭硝子特種玻璃(蘇州)有限公司 に改名

2006年 自動車フロート事業生産開始

2009年 太陽電池カバーガラス事業生産開始

2014年 太陽電池カバーガラス事業生産停止

2015年 自動車加工事業生産開始

2016年 旭硝子汽車玻璃(蘇州)有限公司 に改名

◎本件に関するお問い合わせ先:

AGC 旭硝子 経営企画部広報・IR室長 小林 純一

(担当:宮川 TEL:03-3218-5603 E-mail:info-pr@agc.com)

2015年12月

世界初! 米国皮膚がん財団認証を自動車用窓ガラス全方位で取得 「UVベールPremium Privashield™」で認証取得

米国皮膚がん財団は、皮膚がんの予防や早期発見および治療に積極的に取り組んできた唯一の国際機関です。AGCでは、皮膚がんを引き起こす一因と言われているUVを世界で初めて※3約99%※1カットするフロントドアガラス「UVベールPremium®シリーズ」を2010年より販売し、2013年にフロントガラス「ラミセーフ®」と併せて、これらの製品において同財団から認証を取得しました。現在、運転席および助手席の紫外線対策として、国内外の約50車種※4に搭載されています。

さらに2015年11月からは、これらの製品でご好評いただいた機能を採用したリアドアガラス・リアガラス「UVベールPremium Privashield™」の販売を開始し、この度、同財団の認証を取得しました。これにより、世界で初めて※2自動車の全方位で同財団の認証を受けた窓ガラスによる車内空間づくりを実現します。

AGCは経営方針AGC plus の下、快適性向上に貢献する製品の提供を通じて、今後も世の中に「安心・安全・快適」をプラスしていきます

< 特設WEBサイトはこちら → WWW.AGC.COM/UVCUT360/>

※1 弊社測定値。 ISO9050 基準。

※2 2015年12月現在、 弊社調べ。

※3 2010年12月現在、 弊社調べ。

※4 2015 年12月現在、 弊社調べ。

1.米国の皮膚がん財団(Skin Cancer Foundation)認証ラベル

米国皮膚がん財団(Skin Cancer Foundation)は、皮膚がんの予防や早期発見および治療に積極的に取り組んできた唯一の国際機関です。皮膚がん財団の認証基準を満たした製品には、以下の認証ラベルの表示が認められます。この認証ラベルは世界中の消費者から認められている太陽光からからお肌を守る製品のシンボルです。

認証製品には、自動車・住宅用ガラスおよび窓ガラス用フィルム、日焼け止め、サングラス、日よけ・傘、衣類、洗濯用製品などがあります。

皮膚がん財団に関する詳しい情報は、以下のサイトをご参照ください。

www.skincancer.org/

2.全周約99%UVカットガラス

下記3種類のガラスを併せて使用することで、車に乗る全員の肌を守る全周で約99%のUVカットが可能になります。

2015年4月

AGC、欧州での自動車用補修ガラス事業を強化 ポーランドのNordGlass社を買収

当社は自動車用補修ガラス事業として、欧州では東欧及びロシアを中心に展開する一方、NordGlass社はポーランドを中心として中欧、北欧で同事業を行っています。当社では、自動車ガラス用補修ガラス事業における展開地域を拡充し、補修ガラス製造分野における欧州トップのポジションを確立することを目的として本件買収を行うものです。

尚、本件買収は、欧州独占禁止法当局の承認を前提としております。

AGCグループは、成長分野と位置付ける自動車用ガラス事業において、市場ポジションをさらに強固にし、新経営方針 AGC plus で掲げる企業価値の向上を目指していきます。

Enterprise Investors社

ポーランドの投資会社。1990年設立。

http://www.ei.com.pl/en/about/who-we-are/

◎本件に関するお問合わせ先:旭硝子株式会社 広報・IR室 小林 純一

担当:石橋 TEL:03-3218-56033; E-mail:info-pr@agc.com

2015年3月

AGC旭硝子の鉄道用安全ガラスが北陸新幹線のすべての車両に搭載 - 祝・北陸新幹線開業 -

The Hokuriku Shinkansen Line, which connects Tokyo and Kanazawa, was opened as an extension of the Nagano Shinkansen Line linking Tokyo and Nagano. The newly opened section of the line, which is an extension beyond Nagano to Kanazawa, has many tunnels because of high altitudes and rugged topography. Shinkansen vehicles travel at high speeds that peak at 260 kilometers an hour in very severe weather conditions during winter. Therefore, various functions, including safety, as well as high levels of sound- and thermal-insulating properties, are required of the window glass of the Shinkansen.

東京 金沢間を走る北陸新幹線は、今回開通した長野 金沢間に標高が高く地形の険 しいエリアがあるため、トンネルが多く設けられています。冬には厳しい気象条件の中 を、最高時速260キロの高速で走行します。そのため、窓ガラスには、安全性はもちろん、 高いレベルの遮音性や断熱性等、多くの機能が求められました。

流線形の美しいデザインを実現しつつ運転室の高い視認性を確保する前面ガラス、断 熱性と遮音性に優れお客様を安全に守る客室窓用ガラスをはじめ、前面ランプカバー用 ガラス、行き先表示板用ガラス、内装ガラスなど、すべてがAGC旭硝子のガラスです。

AGC旭硝子には、新幹線を始めとする高速鉄道の安全ガラスを手掛けて50年の経験が あります。今後もAGCグループが持つ素材・技術の多様性を活かしながら、安全で快適 な輸送機器を支える高付加価値製品の開発・提供を推進していきます。

◎本件に関するお問合わせ先:

旭硝子株式会社 広報・IR室 小林 純一

担当:石橋 Tel: 03-3218-560; E-mail:info-pr@agc.com

2015年3月

AGC 旭硝子が「ミラノ国際博覧会」の日本館に協賛 ― 多彩なガラスが日本館の演出に貢献 ―

伝統文化と先端技術が融合した日本館の建築に、当社のガラス素材が彩りを添えます。また、デジタルサイネージを応用したメディアテーブルや空間を広げるハーフ・ミラー等、ガラス技術で芸術性とエンターテインメント性あふれる演出をお手伝いします。

ミラノ万博は、「食」をテーマとした史上初めての万博です。日本館は、「Harmonious Diversity –共存する多様性-」を出展テーマに、日本の農林水産業、食にまつわる様々な取り組み、日本の食や食文化の技などを紹介します。

ガラスのリーディングカンパニーであるAGC旭硝子は、革新的な技術をベースに、空間デザインや次世代のコミュニケーション等、様々な分野で価値の創造に取り組んでいます。今回は、世界中から約2,000万人が訪れる博覧会で、新たな価値を提供します。

AGCグループについて

旭硝子株式会社(AGC)を中心とするAGCグループは、建築・自動車・ディスプレイ用ガラス、化学品、その他の高機能材料を世界のお客様に提供するソリューション・プロバイダーです。100年以上に渡る技術革新を通じて培った世界トップクラスの技術を基盤に、デジタルサイネージをはじめとする様々な分野のニーズに応えてまいります。現在、グループ全体の年間売上は約1.3兆円、従業員数約5万人、およそ30の国や地域でグローバルに事業を展開しています。AGCグループに関する情報は、当社WEBサイト www.agc.com をご覧下さい。

Scene 1: HARMONY

ハーフ・ミラーと映像装置を組み合わせた幻想的な空間。日本の四季の田園風景に没入する五感体験を創出します。

全体を囲むように配置されているハーフ・ミラーは、映像を効果的に反射しつつ、空間の広がりを演出します。

Scene V : LIVE PERFORMANCE THEATER

未来のレストランで展開されるライブ・パフォーマンスショー。観客が囲むメディアテーブルのインタラクションとキャストのパフォーマンス、大型映像空間演出により、一体感のあるショーを展開します。

すべてのメディアテーブルは、ガラス製のテーブルトップを使用。ディスプレイを直接ガラスに貼り合せることにより、クリアな映像を実現しています。

2015年2月

AGC 旭硝子が世界最大規模のデザインの祭典「ミラノサローネ」に初出展

AGC 旭硝子(本社:東京都、社長:島村琢哉)は、今年4月にイタリアで開催される世界最大規模のデ ザインの祭典「ミラノサローネ」に、この度初めて出展します。当社の新製品「infoverre™(インフォベール)」と 「Glascene™(グラシーン)」を用いて、空間体験型のガラス展示を行います

◎AGCおよび製品に関するお問合せ先: 旭硝子(株) 広報・IR室長 小林 純一 (担当:石橋、駒崎 TEL:03-3218-5603、E-mail:info-pr@agc.com

◎本展示に関するお問い合わせ先:デイリープレス 山本 真澄

TEL:03-6416-3201 FAX:03-6416-3202(会期中)+81-90-4062-6361 E-mail masumiyamamoto@dailypress.org

<ミラノサローネについて>

「ミラノサローネ」は、1961年より毎年4月にイタリア・ミラノで開催されている世界最大規模のデザインの祭典です。期間中には、デザイナー等がミラノ市街各地で独自のデザイン性を競う約1,000のイベント(フォーリ・サローネ)が同時に開催され、今日ではこれらすべてを総称して「ミラノサローネ」と呼ばれています。今回当社は、フォーリ・サローネで初めて展示ブースを設けます。

空間デザイン コンセプト

ガラス(glass)と情報(information)で氷河のような空間(glacier formation)をつくる。

肥大化し続ける情報の全体像を、人はもはや把握することはできない。抽出された部分としての情報のみを認識しているのであって、マスとしての情報はもはや環境である。その環境の中に存在する人も、常に否応なく情報を発し、情報の全体像は絶えず変化している。

情報が映し出されるガラスでできた氷河の中に入り込んでいくと、主体=「私」が対象=「情報」を認識するという固定的な関係は変容し、「私」は「環境としての情報」に包み込まれ、体感し、環境の一部となる。そしてさらに、「私」によって環境そのものが変容していく。「私」は、ある時は情報を引き出し、ある時は情報の中に溶け込んでしまう。

情報はあるガラスでは焦点を結び表示されながらも、透過と反射を繰り返すガラスの特性によって薄れていき、環境としての情報になる。「私」は表示された情報を追って空間の中を歩いていくうちに、影として環境の一部となり空間そのものを変化させる。様々な情報のやりとりによって、氷河はきらきらと光り輝きながら変化しつづける。

光を透過・反射するガラスの性質と情報を投影・表示させるという機能を利用して創り出されたこの空間を回遊することで、情報との新しい関係性を体感することが可能となった。

演出・映像デザイン コンセプト

感情や手触り、温度、情緒など、

情報化される一歩手前は、全て体温がある有機的で豊かな営みである。

人類の情報は積み重なり、触れることは出来ないが目には見える巨大なレコードを作り続けることになり、それは意識から無意識になっているともいえる。我々はそのレコードにきざまれた情報を参照し、影響されまたなにかを吐き出し更新している。

接近するか、俯瞰するか。

近寄ることでみえてくるのが個々の人間や関係性で、俯瞰すればそれらが全体値となってある形を成す。

人にフォーカスをあてた情報を元に、うごめく世界を膨大なピースにより表現映像と光によって空間へ投影する。ネスト化され、ゆるやかに接続される人と情報との距離、位置の在り方を体験、かつ、それにより思考や感情の余白を生み出すことを期待する。

クリエーションパートナー

空間デザイン ARTENVARCH(アーテンバーク)

2014年、川島範久と佐藤桂火の共同主宰により東京に設立されたデザインオフィス。

ARTとENVIRONMENTとARCHITECTUREの統合をコンセプトに、建築・空間のデザインからアートインスタレーション・プロダクトデザイン・まちづくり・コンピューテーション・環境シミュレーションまで、分野をまたがった活動を展開中。

川島 範久 (Norihisa KAWASHIMA)(写真:左)

1982年神奈川県生まれ。2005年東京大学卒業、2007年東京大学大学院修士課程修了後、日建設計勤務。2012年カリフォルニア大学バークレー校客員研究員/LOISOS+UBBELOHDE。2014年より、東京工業大学大学院 建築学専攻 助教、ARTENVARCH共同主宰。主な作品=《ソニーシティ大崎》 《HOUSE BB》 《a seed hair salon》他。主な受賞=《日本建築学会賞(作品)》、《日本建築学会作品選奨》、《サステイナブル住宅賞(財)建築環境・省エネルギー理事長賞》他。

佐藤 桂火 (Keika SATO)(写真:右)